Blog > Industrial > Good, Better, Best for Milling Aluminum

Good, Better, Best for Milling Aluminum

5/23/19 | Paul Ashmore, Rexel Technical Consultant

Blog > Industrial > Good, Better, Best for Milling Aluminum

5/23/19 | Paul Ashmore, Rexel Technical Consultant

Hold On! Are you milling aluminum? If you are there is a good chance you are running at very high spindle speeds! It is very common to see CNC mills with 10,000-20,000 rpm spindles.

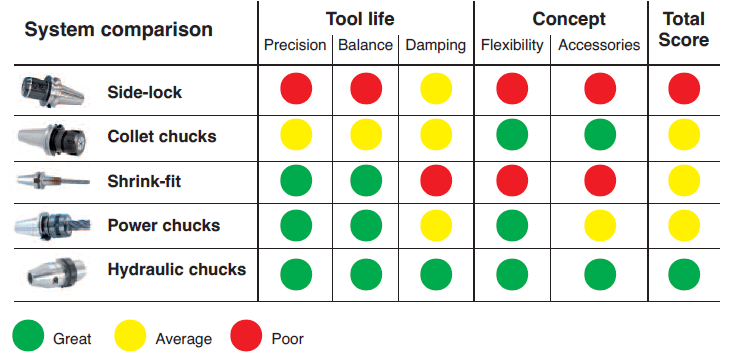

With that kind of spindle speed, you better make sure your high-performance endmill is held in the right toolholder—ER collets and side-lock endmill holder’s need not apply. Why, you might ask?

ER collets do not grip the entire length of the shank, which can cause a pivot point where the tool may move under a heavy load. Runout can be .02-.04 mm on the tool. ER collet holders are perfect in a job shop environment with their collet size flexibility and price point. Side-lock endmill holders are strong in griping but many brands are poorly balanced, so you lose concentricity with tool runout.

Tool runout causes chatter and poor tool life. That leaves us with pressed systems/manual milling chucks, heat shrink, and hydraulic holders. These toolholder’s all work well. As I mentioned with high spindle speeds, you want the least amount of runout and best concentricity available.

Good – Pressed system /manual milling chucks are very popular with high accuracy and offer you flexibility by changing endmill size with precision sleeve. For pressed systems, a loading fixture is required. These holders can be prone to locking up and or wearing out.

Better – Shrink fit is also very accurate, but keep in mind as the holder is repeatedly heated and cooled tool runout may increase. A limit of one size shank per holder also leads to more holders in inventory. Heating unit required.

Best – Hydraulic holders are the lowest runout holders available and allow the flexibility of using precision sleeves to carry other size endmills/drills. Less tool runout leads to longer tool life and better part finishes. One thing I like best about the top brands of hydraulic holders is the quick load/unload of the tool using a pre-set torque wrench—no more wrench slips and bruised knuckles.

A best practice is to make sure the tool shank is loaded into the holder because membrane damage may occur without the shank being present during activation. Please note, not all hydraulic holders are made the same, some manufacturers use oil in the chamber while others may use grease. The extra cost associated with the top brands is well worth it in the long run because the quality and performance far exceed replacement cost and potential downtime with lesser quality holders.

So, next time you crank up the spindle to machine aluminum, give plenty of thought on how you are holding your tool.

Whether you’re milling aluminum or cutting stainless steel, we can help you find the right tool for the job. Our in-house expertise with industrial cutting tools and long-standing relationships with tooling manufactures will help you increase efficiency and reduce waste. Contact us today!