Blog > Automation > Benefits of Using a Line Reactor on AC Drives

Benefits of Using a Line Reactor on AC Drives

8/10/22 | Scott Savage, Rexel Technical Consultant

Blog > Automation > Benefits of Using a Line Reactor on AC Drives

8/10/22 | Scott Savage, Rexel Technical Consultant

This post is part I of our In and Out Trilogy:

Read Part II here

Read Part III here

Line reactors tend to be viewed as an optional piece to a drive installation. In fact, they are in the correct situation.

- The device requires more panel space or wall space

- Line reactors add to the cost of the installation

- You feel it is an extra unused piece to the overall system

- They are bulky and require more labor to mount

- If it is so important, why is it not included in the drive?

- Others have added them in the past and nothing happens

- You are confused – do the reactors go on the line-side or load-side?

- Why do your specialists keep asking about the supply transformer if it is not part of the installation?

- You are just trying to sell me something I don’t need

- Others say you don’t need a line reactor - why do you?

- I am not going to add the reactor after the installation - it is too late

Human beings all like the least path of impedance. Ironically, impedance is what we are about to touch on later in this blog. The fact is everyone tries to maneuver around physics. “It’s going to be different this time.” In physics, no it is not.

The fact of the matter is drive manufacturers want to fit in everyone else’s physical location to gain market share, so the line reactor was a large component and was removed. That left the consumer the free agency to decide whether to use the reactor or not. Sometimes you will not need a line reactor and sometimes you will.

People forget that most people don’t keep track of how old the drive is. Without the reactor, they shortened the life of the drive significantly. The fact is, in certain situations, it does matter if the reactor is in a circuit. For a little money, you have extended the drive life by years! Then you will forget how long the drive has been in for.

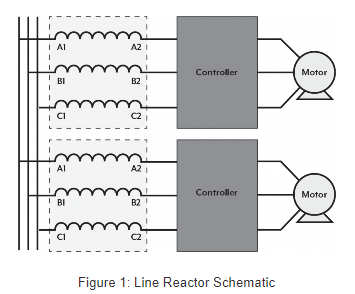

Line-side reactor (suggested HIGH 5% impedance)

Courtesy TCI

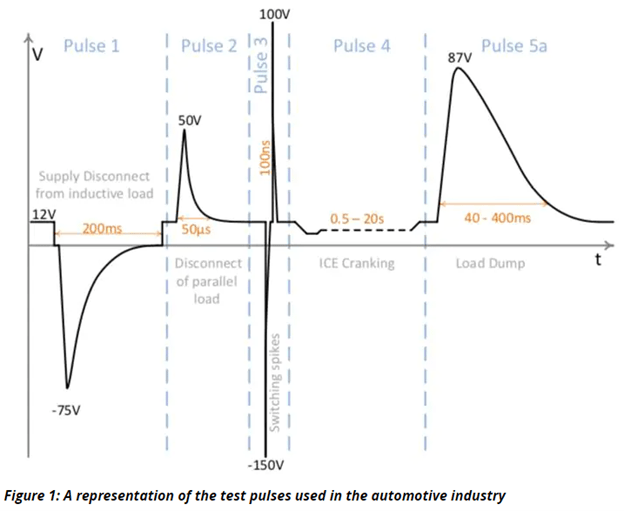

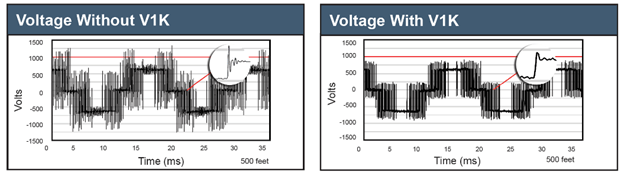

Transients are rapid rises in voltage

Special thanks to Diodes (Transtector division) lighting specialists

Transients damage MOV protection and eventually destroy the bridge (rectifier) of drives. Line reactors round these transients to much lower levels. This may happen if the drive is operating or just idle in your facility. This improves the life of the drive primarily during events (lightning activity) or just re-energizing a large supply transformer in your facility.

Just wait – if you already knew this, GREAT! BUT there is more to come. Keep reading.

This applies in MCCs where floor space is valuable and line reactors may be eliminated to preserve space in electrical rooms. Consider mounting the line reactors in NEMA1 cabinets on top of the MCC.

Large transformer on small drives

PF525 COMPONENT DRIVES (KVA XFRMR/DRIVE HP) > 10

10:1 RATIO AND ABOVE

PF750 ARCHECTECT DRIVES (KVA XFRMR/DRIVE HP) > 20

20:1 RATIO AND ABOVE

So, the larger the drive the line reactor becomes a matter of choice due to the lower transformer-to-drive mismatch.

The larger the line reactor, the lower the impedance, so if you elect to place one line reactor in front of an MCC for example, the impedance is less. It is preferred to have individual line reactors in each bucket on smaller drives. It does work, but the protection attenuates significantly.

Note: PF525 drives below 15HP have no DC link inductor on the DC bus. In fact, most manufacturers have removed them on smaller drives. These were removed after the bridge to reduce size and cost. Link inductors were used to reduce ripple on the bus and make the bus more stable. Voltage source inverters are capacitor-based devices and can be extremely volatile. No line reactor and no DC link inductor opens the opportunity paired with a large transformer to cause catastrophic events. Just from a safety standpoint, the line reactor is worth the small amount of money. Another reason to protect your personnel.

Line reactors also reduce harmonics on your electrical distribution and decrease wave distortion, which is lost as heat instead of kinetic energy. Some industries require to abide by IEEE519 and are required. This eliminates the need to apply a harmonic filter, which is costly. 30HP and above require a harmonic filter. Below this HP rating, a line reactor may be an excellent solution.

Well, if you knew all this – I have one more important fact you may not know about, and to me, this is the most important fact. I alluded to it earlier, and that is safety. Inductors are current-limiting devices.

This applies whether you have a DC link inductor or not - plain and simple. Reduce your devastating current inrush, especially on a ground fault or a bus failure i.e., a ruptured capacitor on the bus. Protect your investment surrounding the drive and your personnel. If you have a breaker in front of the drive, please use a line reactor. The breaker is slow to react vs. fuses.

It is never too late to add a line reactor. Please reconsider your application without a reactor and take the time to save yourself lots of aggravation.

If the installation seems to do nothing - it is doing exactly what it’s designed to do. Do not be deceived or let someone convince you differently – it is an important part of your drive project.

The benefits outweigh the cost and size of the device - consider it a great insurance policy!

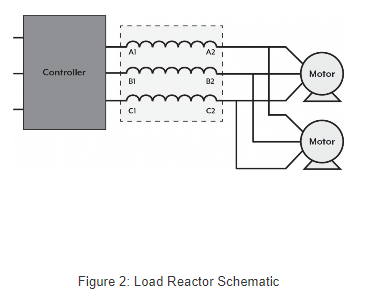

Are you still with me? Great! One last thing from our list at the beginning of this blog: Load reactors. On the output of the drive, the load is on the output of the drive between the drive and the motor. The line reactor is between the branch protection and the bridge of the drive (front end). The generic term is “line reactor” and is confusing. It really is a load reactor.

OK – two reactors on the drive? Possibly.

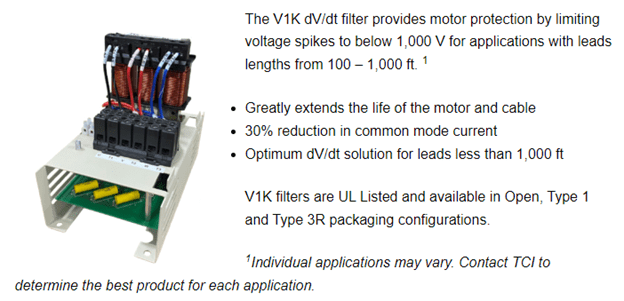

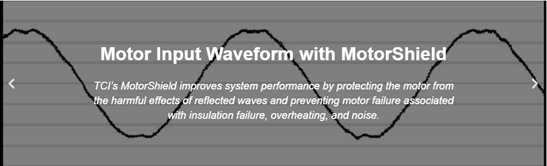

Long lead lengths between the drive and motor over 150 ft may require a load reactor. I consider this an old-fashioned approach. Put a dv/dt filter (low pass) to clip the IGBT glitches (ringing) instead of the load reactor, so you eliminate the voltage doubling at the end turns of the motor. This way you don’t get corona (bubbling of the first windings of the motor) and burn up the windings. The cost of the filter is slightly higher in cost than a load reactor and has a load reactor incorporated in it with a filtration board mounted at the load reactor. The dv/dt is mounted near the drive output. These are good to about 1000 ft. Just a load reactor is good for about 400 ft and just rounds off the IGBT cresting and costs almost as much as the dv/dt filter. After 1000 ft, use a sine wave filter (MotorShield), which reformulates the rough wave form from the rough wave output on the drive to a completely clean sinusoidal wave. Remember, if you run one drive on multiple motors you must add each run to each motor and total the entire length to determine which device you will need.

Load Reactor (Low Impedance 3%)

It is rare to find the load reactor down near the motor. It can be done but reduces motor torque by approximately 10%.

MotorShield sine wave filter

Courtesy TCI

I hope you have enjoyed this blog. Horizon Solutions is here to assist in any way we can. Our specialists frequently enjoy going into the field with our customers and we walk the walk, not just the talk.

These solutions have worked for me for the past 26 years. Hopefully, you might take one idea on how to make your next installation a better one.

We wish you luck and please be safe out there!

Questions? Need help? Contact us today!