Blog > Automation > Improving the Performance of Pumps and Fans

Improving the Performance of Pumps and Fans

5/3/22 | Scott Savage, Rexel Technical Consultant

Blog > Automation > Improving the Performance of Pumps and Fans

5/3/22 | Scott Savage, Rexel Technical Consultant

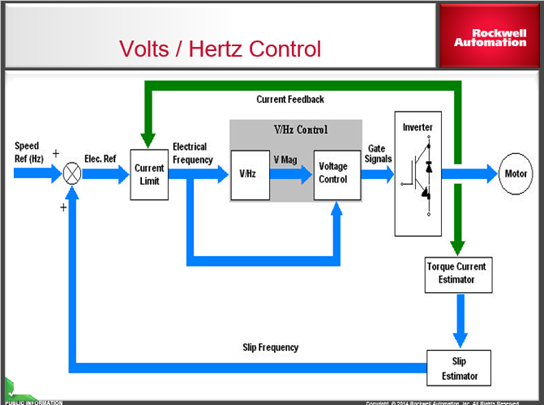

Here’s something that many of us ponder: Am I getting the best performance out the VFDs (variable frequency drives)? Whether you’re preparing to install a VFD or have previously installed one, wanting optimal performance is natural. This blog will address two of the three operation modes (V/hz & SVC) and when to use each mode, allowing for the best and most reliable characteristics of the drive to improve the performance of your pumps and fans.

We’re now in the digital era of AC drives, exceeding the performance of DC drives that were so prominent prior to mid to late 80s. Those pesky (but convenient) trim potentiometers on DC drives made us all feel like experts as we made adjustments.

The AC drive technology now locks into the parameter selection and no longer drifts like analog DC drives of the past. The fourth industrial revolution demands reliability and consistency. Not only do modern AC drives stay consistent, but in the motor control mode, you can also program the drive for different modes. These modes can make a big difference, adding to the performance and efficiency of the system and allowing it to respond to different types of loads on the motor.

So many times in the field I hear, “It’s an electrical problem” or “It’s a mechanical problem” as if they are two separate issues. It may be better to rethink “electrical” or “mechanical” as two components that work together to solve a problem. The load, which is mechanical, affects the drive. It is important to understand the actions of the load upon the drive and the dynamics it will cause. Trying to separate the two is a recipe for failure; the drive team must view the entire system from the drive to the load itself.

1) Static Tune – If the load cannot rotate while attached to the motor, this is the only alternative. The performance is limited, but it’s better than out-of-the-box performance.

2) Rotate Tune – This provides optimal performance and is superior to static tuning. Your load must be released from the motor shaft (SVC only).

SVC for Normal Duty loads is used when you cannot achieve break-away torque with a Fan Curve or Custom Boost shown later in the article. All motor data needs to be entered in this mode.

SVC control is a dynamic boosting algorithm that requires a minimum Static Tune with a motor coupled to load with pumps and fans. Please keep in mind that SVC does not give you the fan curve frequency/voltage (1/x2) voltage on the acceleration of the drive discussed later in the blog (energy that can be saved).

V/Hz – Requires no autotune for the motor. The only motor data that needs to be entered is the motor amps to protect the motor from an overload situation. If motors are changed, there is no re-tuning of the drive. Performance is average—great for improving the performance of centrifugal pumps and fans.

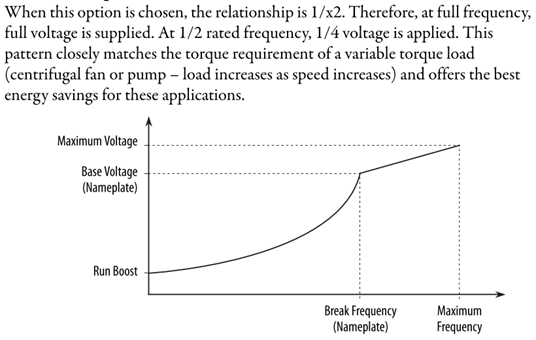

Typically, a fan curve gives a choice of predetermined curves as shown below. Initial startup torque can be programmed with an additional boost if needed. The fan curve remains the same after an initial boost, unlike the ability to change the V/Hz ratio in a custom curve. An increase in run boost adds a slight trim to the torque shown in the curve.

Large inertia loads such as induced draft fans and force air fans should run in a custom curve, instead of a fan curve, for better control of startup torque. SVC is also a consideration for the improvement of startup torque performance of your pump or fan.

Observe the standard fan curve, which does not provide a large amount of torque upon the start-up of the pump or fan. Centrifugal pumps and fans normally do not require significant torque on startup. Torque on the upper end of the curve will increase due to the dynamic head pressure in the system as the flow increases to full speed.

Run boost can add additional low-end torque to provide a smoother run and acceleration response.

Custom Boost would be used fans of large diameter and mass, typical applications include:

1) ID Fans

2) FD Fans

3) Evaporators

4) River pumps

5) Large Influent Pumps

These applications demand more start-up torque and may warrant using a custom boost instead of a normal fan curve.

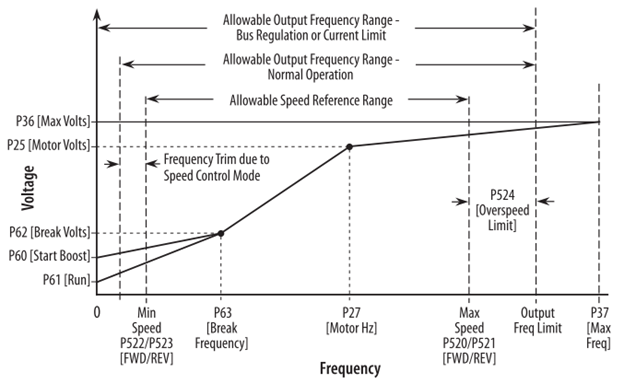

Shown above are parameter numbers for a PF750 series drive from Rockwell Automation®. The start boost will be applied at starting of the drive under load. This provides more initial torque prior to acceleration since you are looking to improve the performance of your pumps or fans.

Additional torque is added upon acceleration and while the drive is achieving commanded speed to operate the load in your process.

These settings correlate to each other. The custom boost slope observes these two settings, and you manually adjust them together to achieve better acceleration torque. This allows the load to break free and should be set to achieve good acceleration. Please keep in mind the acceleration torque will change when break frequency and break voltage is a manual adjustment. Dynamic boosting is done with SVC and is not a manual process, and is not the scope of this blog. Please refer to part two of this series on Heavy Duty applications to understand this concept.

How can we adjust the torque? This is achieved by the V/hz ratio by changing to slop of the curve: TORQUE = VOLTS/Hz

Increasing the Break Voltage will make the slope steeper providing more torque on acceleration.

Increasing the Break Frequency will flatten the slope and provide less torque on acceleration.

Any combination of the two affects the torque depending on the percent slope provided.

This process is a trial and error please observe the performance of your pumps and fans and adjust accordingly.

Any speed reference above motor base speed hertz will not be discussed in this blog. Please keep in mind above the base speed of the motor places the system in constant HP. The increase in speed will attenuate the torque. Motor speeds above 90hz leaves little torque with high flow rates.

Just nameplate motor amps for V/hz need to be entered for the protection of the motor. There is no Autotune. Replacing motors does not require any additional programming of the drive.

This concludes our pumps and fans performance blog, please join us for Part II of the series where we will discuss Sensorless Vector and Flux Vector applications. V/hz mode is the simplest form of motor/torque control and the only way to control motors until about 1995 when the 1336Plus drive V4.0 firmware version was added to achieve dynamic boosting with Sensorless Vector Control. This algorithm changed the way we programmed drives. The V/hz concept for most was abandoned for the automatic boosting capabilities, but there are many applications such as pumps and fans where this mode should be used today.

We hope this is of help to you as you make your choice on motor control in the future. It does not need to be complicated, just an understanding of simple applications without a lot of programming/engineering time put into your many applications. If you have any questions or need assistance, please contact us today!