Blog > Automation > Capacitor Reforming for Legacy Drives

Capacitor Reforming for Legacy Drives

11/12/19 | Scott Savage, Rexel Technical Consultant

Are there legacy drives lurking on your store-room shelves? While having a back-up is always a good practice, you may have to perform a step or two before installing one of these drives that have been gathering dust. Let’s examine capacitor reforming.

Sitting on the Shelf Too Long

Many manufacturing facilities place a top-of-frame drive on their shelf as a spare unit in case any of the drives fail on the plant floor. It is a good practice to have a spare to do an immediate replacement. But what happens if the spare sits on the shelf for a few years? Most people might think that it is a blessing and just wait until a working drive fails and replace the failed AC drive with that five-year-old drive from the shelf.

Most stock room clerks, drive technicians, and sometimes engineers don’t realize the drive may have sat on the shelf too long and need to be reformed prior to installation. To understand this circumstance and why capacitor reforming may be necessary, let us take a quick look at the construction of electrolytic capacitors used in AC drive technology.

Electrolytic Capacitor Construction

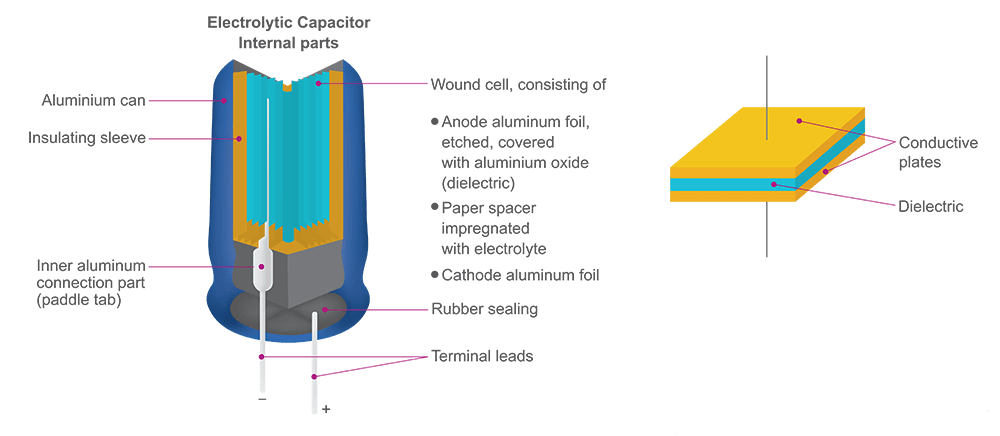

Capacitors are made of an anode and cathode with a film placed in between the two electrodes made of paper impregnated with an aluminum oxide which acts as a dielectric. The dielectric allows potential charge between the anode and the cathode depending on the distance between the anode and the cathode, and the surface area of the two electrodes determines the charge in Farads. Most of us were exposed to this concept in a physics class.

The figure below shows the simple construction of an electrolytic capacitor. The can, which is the outside container, holds a special oil that exists between the spiral layers of electrodes.

Please keep in mind capacitors are like batteries, when the electrolyte dries up, the capacitor should be thrown away. If the capacitor is only several years old there is a great possibility the aluminum oxide layer can be reformed, if there is electrolyte in the can.

When Cavities Align

During the time the capacitor sits on the shelf, the aluminum oxide can settle and form small cavities in the aluminum oxide, exposing the anode and cathode surfaces to each other. If the cavities line up and are large, this could provide an internal short on the DC Bus. That can be a potential safety hazard when energizing an older drive to put into service for the first time.

Please be aware of this before you energize the drive—it could cause catastrophic damage to the drive and to personnel even when wearing proper arc flash equipment.

Capacitor Reforming Service

Rockwell Automation® has a service to reform capacitors at your facility, with the work performed in just one day. The procedure may take a few hours but is well worth the effort to reform instead of purchasing a new drive or even an exchange drive from the Rockwell Automation repair loop. Please contact your local Rexel Drives Specialist for a drive capacitor reformation if you feel the least bit uncomfortable with charging up the DC Bus on the drive. Remember at 480 VAC, after you rectify onto the DC Bus, it is 675 VDC and extremely dangerous, even on a workbench.

DIY Capacitor Reforming

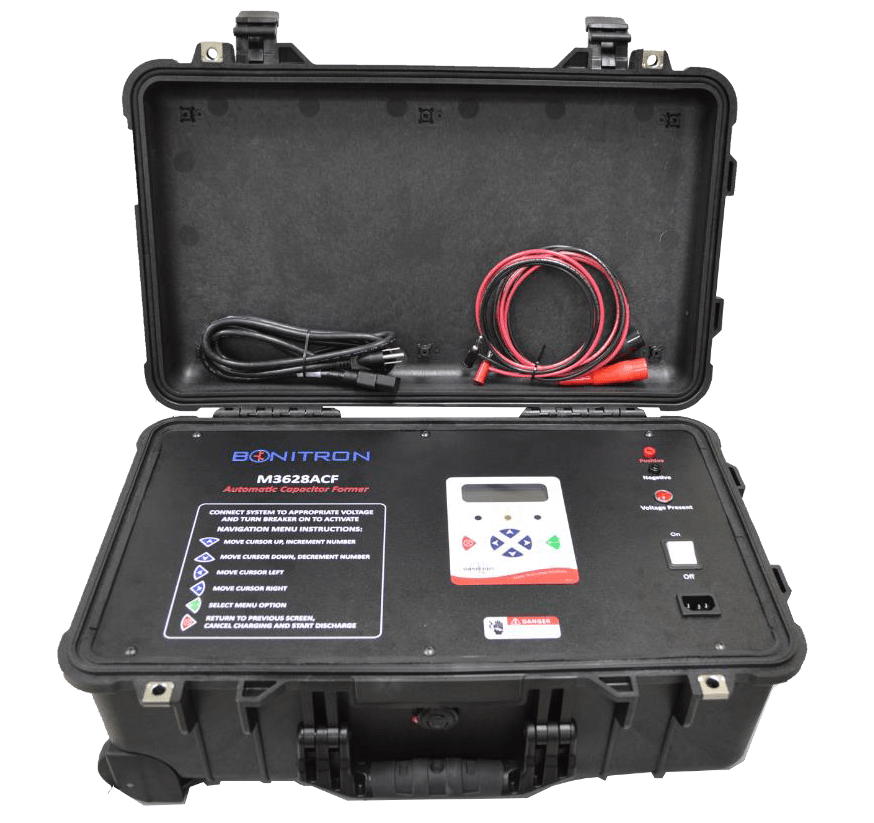

The 3628ACF from Bonitron automatically takes you through the steps of reforming the capacitor bank. The user manual listed on the Bonitron website describes the individual settings to correctly run the sequence of events. The concept is, start at 10% voltage 600 seconds, and then hold for 900 seconds on the DC Bus. Repeat the procedure until the capacitors are at maximum voltage, monitor for voltage increase on each step up, and observe as the voltage gets greater that there are no strange noises and no excessive leakage current. The maximum voltage is 1000 V and the maximum capacitance is 300,000 uF for the model 3628ACF.

Bonitron Do It Yourself Solution M3628ACF

The 3628ACF avoids the use of individual testers to measure equivalent series resistance and high voltage leakage testers, along with the special knowledge to run and monitor each tester accurately. It is all built into one unit. Feel free to check it out.

We Can Help

Thank you for reading! If you have an interest in legacy drives, check out some of my previous posts. And feel free to contact any of our Power Specialists for more information regarding this very important procedure. Please always be safe out there!