Blog > Automation > Applying CIP Safety with Rockwell Automation

Applying CIP Safety with Rockwell Automation

11/23/21 | Scott DeVost, Rexel Technical Consultant

Blog > Automation > Applying CIP Safety with Rockwell Automation

11/23/21 | Scott DeVost, Rexel Technical Consultant

I can remember the days of looking in an industrial enclosure and seeing a cabinet full of relays and a mass of wires running through the wireway. I remember thinking what a challenge it must be to troubleshoot a problem with all those wires and relay connections. Now when we investigate an industrial enclosure, we see a PLC typically in a much smaller enclosure with a lot less wiring. The benefits of switching from relay logic to a PLC are taking place now in the safety world. Banks of safety relays can now be eliminated and replaced by a CIP Safety™ device connected to a GuardLogix® or Compact GuardLogix safety PLC from Rockwell Automation®.

CIP Safety devices are connected to the same Ethernet/IP network as the other machine devices, utilizing the same network. The CIP device is responsible for confirming the integrity of the data, and if an error occurs, it will go into a safe state. There is also a CIP Safety application layer that validates the integrity of the safety data transfers between the safety PLC and the CIP Safety device. There are time stamps and production identifier information that are contained in each packet to ensure that the data is from the expected device as well as within the time expected.

CIP Safety has been certified by TÜV Rheinland® for use in functional safety applications. Some other benefits of CIP Safety over safety relays are the communication of diagnostic and status information to Logix. Changes can be made in software versus hard wiring changes on the relays. One software for configuring, monitoring, and maintaining. This is important for some customers because they don’t want multiple software packages that they will have to keep up to date and support. Studio 5000® add-on profiles can reduce programming and installation time.

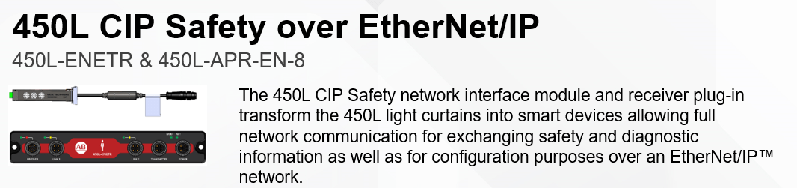

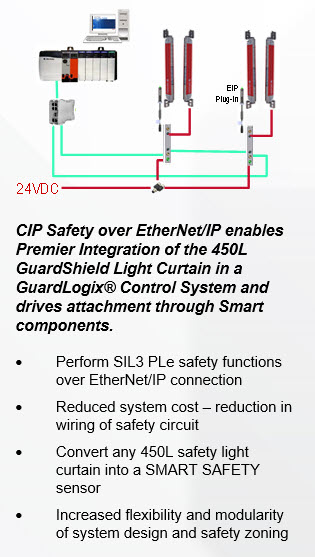

Below is the CIP Safety network interface module that allows you to convert any of the Allen-Bradley® 450L safety light curtains into a CIP Safety light curtain. The 450L light curtains are a transceiver design, so they are configured by the plug-in module as either a transmitter or a receiver. By utilizing the plug in below as well as the interface module you will have a CIP Safety light curtain.

Below is the latest CIP Safety laser scanner that allows you to scan out to 5.5 meters and 275 degrees out from the unit. This type of device is a great alternative to safety mats as it gives you a complete area of protection like the safety mats, but it is easier to configure and implement especially now that it has CIP Safety and add-on profile in Studio 5000® software.

Click here to learn more about the SafeZon 3 CIP Safety Laser Scanner

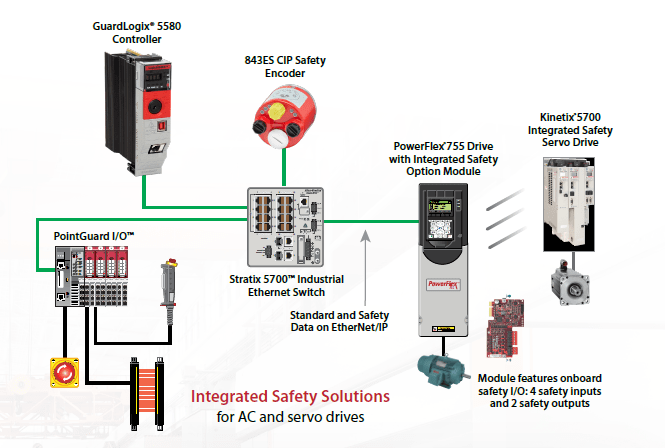

Below is the CIP Safety Encoder offering from Allen-Bradley. With these CIP encoders, you can do applications such as safe speed, direction, or position up to a SIL 3 PLE rating. These safety functions are built into the GuardLogix controller and can utilize EtherNet/IP can help reduce the hardware and installation cost.

Click here to learn more about the 843ES CIP Safety over EtherNet/IP Encoders

The final CIP Safety device that I would like to present is the CIP Safety door interlock box below. This interlock is a great solution for full-body access applications. It can be configured with two buttons, or E-stop (emergency stop) and two buttons, or E-Stop, four buttons, and an enabling switch connector. There is also an option for an escape release handle. Because this is a CIP Safety product the standard control and the safety can go over EtherNet/IP, saving time and hardware costs.

In summary, CIP Safety is a great way to eliminate safety relays in a cabinet, configure complex safety applications easily, get status and diagnostic information, utilize one software platform, and utilize AOP in Logix to reduce programming and installation time. Control panels and technology have changed a lot over the years, and I’m sure there will be a lot more to come. We’re here to help you stay on top of technology and make the right changes for your facility. Contact us today!

Images and brochures © Rockwell Automation