Blog > Automation > Accessing Critical Spare Parts at a Distance

Accessing Critical Spare Parts at a Distance

4/2/20 | Michael Martinson, Rexel Technical Consultant

With COVID-19 ruling the headlines, you may have some questions about how you’ll keep your essential business up and running. For example, “How do I ensure immediate access to the critical spare parts I need, yet still maintain social distancing?”

We’re all waking up to a new reality of doing business. Through these difficult changes, it’s more important than ever to make sure each of us is less reliant on face-to-face interactions. This presents an especially difficult challenge when maintaining supplier relationships and accessing critical spare parts.

Now more than ever, the average American is counting on our factories to have a game plan in place to keep all of us sustained with the vital goods you make! So, how will you get the parts you need to keep production up and running?

Parts Management Agreement

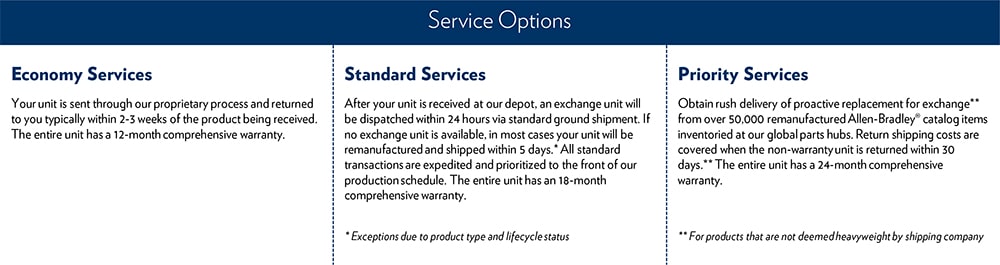

Let’s take a dive into what we call our Parts Management Agreements (PMA). With a PMA, critical spare parts are located at your facility, so you have 24x7x365 access, while we own and manage the inventory for a fixed fee. As social distancing becomes the new normal, maintaining your required inventory levels without in-person supplier interactions is simplified through this program. As the need to replace spare parts that were consumed arises, our customers simply notify our Rockwell Automations services group via email with the item number. We then offer a variety of service levels based on your immediate needs.

A Hands-Off Approach

Once you select the service level that best suits your immediate requirements, we issue all the necessary paperwork via email. Then you send out your failed unit and await the arrival of their replacement. This process involves pretty much no human interaction aside from the shipping company picking up and delivering your product.

Remanufacturing and Renewal

The agreement is backed by our remanufacturing and renewal parts services to replenish any inventory used. Utilizing our remanufacturing service offers you these benefits:

- Immediate availability for critical spare parts onsite

- Increased uptime of production equipment

- Reduced mean time to repair (MTTR)

- Improved control of inventory assets

- Decreased inventory carrying costs

Flattening Operating Expenses

In addition to limiting the human interaction within facilities, our customers can count on the added benefits of a PMA as follows.

- Warranty: The warranty clock starts when equipment is removed from PMA stock (in-service warranty).

- Flexible Inventory: PMA stock can be returned, and next-generation products can be added to the agreement to keep up as you modernize aging equipment.

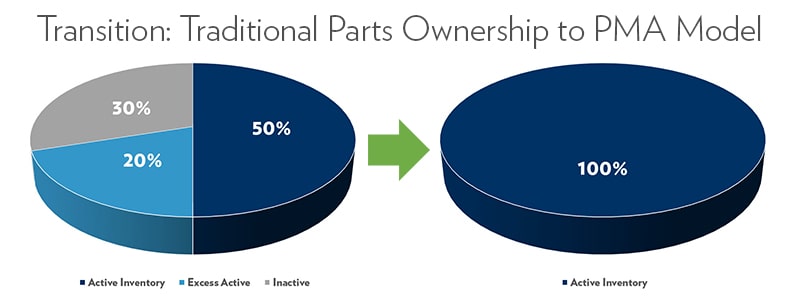

According to our internal data, approximately 50% of a customer’s typical inventory is not used in their installed base. This material is either excess inventory based on current plant requirements or supports equipment no longer in production. The Parts Management Agreement breaks from the traditional parts ownership model, which can result in unnecessary and out-of-date inventory. PMA is a vendor-managed inventory model with access to critical spares parts.

We Can Help You Manage Critical Spare Parts

How much excess inventory is your storeroom carrying today? Contact us today to learn more about how our remote services can help you through these challenging times!