Blog > Automation > 5 Steps to Digital Transformation Success

5 Steps to Digital Transformation Success

1/23/20 | Jim Bischoff, Rexel Technical Consultant

If you are like me, you have heard a lot of buzz in the industry about digital transformation. Depending on what you read, statistics show that 60 to 80 percent of digital transformation initiatives fail. That is a mind-blowing statistic and would likely explain why I see the manufacturing community moving slowly. Maybe you are just trying to figure out what digital transformation is and how it can help you and your company, or perhaps you are trying to figure out where to begin on your journey.

Digital Transformation – A Simple Definition

If you have done any research on this topic, you will find many diverse definitions of what digital transformation (or DX) means. It seems odd to me that a term with such varying definitions and interpretations is used so abundantly. I like to think of it in much simpler terms. Digital transformation is using information that should be available to you today to increase your productivity and profitability and to maintain your long-term viability. Yes – my definition is still a little vague, but what manufacturers need to do to be productive, profitable, and viable varies.

To create a success plan, you must discover your “need to dos.” My definition of digital transformation refers to “information that should be available.” Understanding the information that all the stakeholders need and the data that you currently have will allow you to identify what needs to be done.

Side Note: I try to differentiate data and information. Meaningful information comes from processing raw data. You may have a plant historian capturing hundreds or thousands of data points. Until you process that data and turn it into meaningful manufacturing information—it is still data.

Think Big, Start Small, Scale Fast

You have probably heard this phrase before, but you need to think of it as three distinct steps. Let’s look at how it relates to digital transformation.

#1. Think Big

This is the discovery phase. This is the “What,” not the “How.” Here are some questions to ask yourself:

- What is limiting my productivity and profitability?

o Possible Answers: Unplanned downtime, excessive scrap, OEE, capacity limitations, regulatory compliance, etc.

- What may be impacting my long-term viability?

o Possible Answers (in addition to above): flexible manufacturing, skills shortages, rising capital investment costs, agile response to consumer demands, global competition, etc.

Once these questions are answered, continue to dive deeper.

Example: What information do I need to understand why xxx is limiting my productivity? Does that information exist today? Where should it come from (control system, business system, etc.)? In which direction does the information need to flow? Unidirectional or bidirectional? As you look at different areas of your manufacturing process, are you finding common themes? Can you prioritize the productivity gains? Are you willing to challenge the status quo? Just because you have always waited until Monday to review the previous week’s efficiency reports doesn’t mean you can’t implement a live OEE solution.

In order to think big, you should ask these questions to each of the key stakeholders in your company.

#2. Start Small

As I read about the high failure rate of digital transformation initiatives, it appears many that failed adopted a “Think Big, Start Big” approach. Digital transformation not only requires technology changes but cultural changes as well. Too much change at once causes stress and will likely lead to failure. Unproven pilots may not scale well.

If you followed step one above, you most likely determined that additional information is needed to positively impact your productivity. Having this information will also give you a good idea where you should start small.

Time to ask yourself more questions:

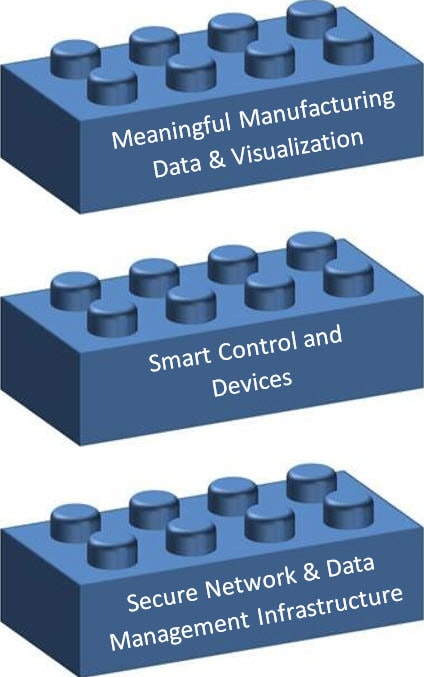

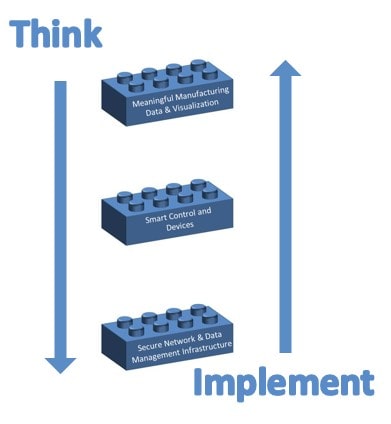

- How will I display the information I need? Who needs to see it? Where do they need to see it (local, remote, mobile, etc.)? How often does it update (real-time, daily, etc.)? Where does it come from? Do I have a hardware and software platform to visualize the data? Is it scalable? Is it secure?

- Do my assets produce the data I need? Do my control systems support adding smart devices that produce that data? Are my control systems current technology? Are they supported (by you AND the vendor)? Are they scalable? Secure?

- Do I have the appropriate infrastructure to support the above? Are my assets networked? Is my network stable? Is my network scalable? Is it secure?

Forcing yourself to focus on the above building blocks will increase your chances for success. Challenge yourself to think about them from the top down but invest in the solutions from the bottom up. You can’t have all that great information you need without devices that produce the data, and the infrastructure to connect it all together.

Focus on the infrastructure first. Be sure it is robust, secure, and scalable. Consult with industrial networking experts and invest in assessment and design services, if needed.

Then add those smart devices (IIoT Sensors) that you need, like pressure, vibration, temperature, speed, counts, etc. Talk to your control system partner and ensure your assets can support the technology needed. Invest in lifecycle assessment or modernization services, if needed.

Invest in scalable platforms for data visualization. Get together with your IT department and weigh the options of virtualization, on-site hosting, cloud hosting, thin clients, etc. Again, consult with industry experts that work with manufacturing, not just IT organizations.

The previous three steps can be done as a part of a proof of concept (PoC) or in preparation for that project.

#3. Scale Fast

Step two should have gotten you to a PoC. But before you scale, you need to evaluate.

- Was the PoC project successful?

o Did you improve productivity, profitability, or viability?

- Did you get cultural buy-in?

o Are people comfortable with electronic information vs. printed reports?

o Are people using and trusting the technology that has been implemented?

- Does the technology selected appear to be scalable to meet your overall objectives?

o Now is the time to reevaluate BEFORE you scale.

You need to be comfortable with your answers to these questions before you scale up to a production line, an area, or an entire facility. Address concerns and move forward.

Remember:

- Don’t get dragged down by the minutia.

- Don’t wait for the next latest and greatest technology.

- Ask yourself the cost of NOT increasing your company’s productivity, profitability, and viability by scaling.

#4. REPEAT

The projects I have seen that go from determining desired business outcomes to successful proof of concept have taken from as little as six months to 2-3 years or longer. In that time, market conditions, customer demands, technology, and regulations may have changed dramatically. Put a plan in place to circle back and ensure that your big thoughts are still driving you to enhanced productivity, profitability, and viability. Work with your consultants and delivery partners to tweak your plan to accommodate these new demands. Success is always a moving target.

#5. Select the Right Partners

This a critical step and is really a sub-set to steps one through four. To choose the right partner, you will need to determine the qualifications. Here are some possible examples.

A good partner:

- Understands your desired business outcomes and is available to consult.

- Wants to help you, not just sell to you.

- Knows your industry segment and has experience with similar organizations.

- Is well respected in the industry.

- Is in it for the long haul and will stick by you through thick and thin.

- Knows the technology required and has experience in its implementation in similar applications.

- Has a network of available resources that also meets the above criteria.

- Knows their own limitations and engages those resources when appropriate.

We Can Make Your Digital Transformation a Success

Rexel, Rockwell Automation®, and our extended PartnerNetwork™ have a long history of helping our customers achieve their goals. We have domain expertise in all vertical industry segments, as well as application expertise across our technical solution portfolio. We provide pre-sale and post-sale consultative support, as well as a host of assessment services, project management, and turn-key project implementation. We would like to be your partner in your digital transformation journey. Contact us today!