Blog > Automation > The Power of the E300 Electronic Overload Relay

The Power of the E300 Electronic Overload Relay

12/15/20 | Tom Hopkins, Rexel Technical Consultant

Motor Diagnostics – Knowledge is Power

In this new age of manufacturing, you are being told you need to do more and more. Not only are you tasked with improvement projects and keeping the production lines running, but upper management is talking about the Internet of Things (IoT). They want you to figure out how to collect production data, what machines are up and running, how much is being produced on each line at any given time. They are even talking about calculating the power demand on each production line.

We can help you with much of your above workload with a simple device: the Allen-Bradley® E300™ electronic overload relay from Rockwell Automation®.

Preventive Maintenance

Unplanned downtime can be a real drag. You have plenty of projects on your plate, and unplanned breakdowns really make your life difficult. In addition, the boss has production quotas, and you need to keep the machines running. Having the right tools and data to stay ahead of unplanned failures is a must.

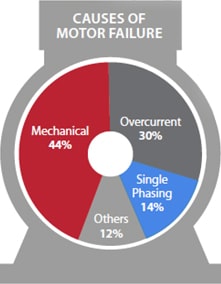

Let us talk about your motors. What are the most common reasons for motor failure?

Like most facilities, you probably protect your motors with overload relays. An overload is a great tool and will keep your motors safe from an overcurrent condition (provided you have it set correctly, of course). A single-phase condition is more effectively detected by an electronic overload than bimetallic or eutectic alloy overload, so hopefully, you are using the latest electronic technology.

But what about the 44% of motor failures caused by mechanical issues, an overload cannot detect this. Let us say you have a bearing starting to fail. This condition will cause more current draw in a motor, but not enough to trip an overload. You could set up a power monitor to detect the increase in current, but that is just one more device to maintain. How about using the next generation E300 electronic overload relay? This overload relay performs all the functions of a motor overload PLUS many other features to help with preventative maintenance and diagnostics.

Information is Power

In the bearing failure example, the E300 electronic overload relay will read the current draw increase and can make you aware before a breakdown occurs. You can also use this device to track voltage and energy usage, allowing you to be aware of a voltage imbalance before it causes an issue. The energy tracking feature enables you to give your boss the energy usage information that he is demanding.

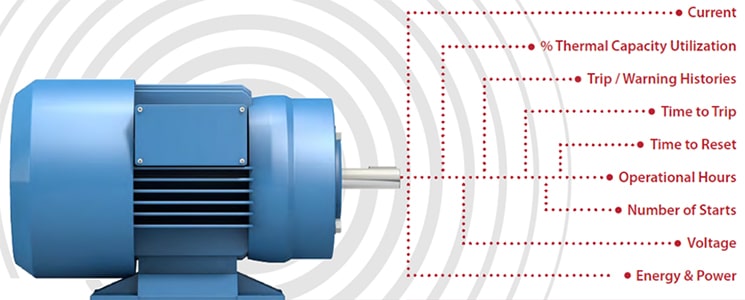

You may wonder, how else can the E300 electronic overload relay device help me? There are several helpful features that can trigger either manual or automatic intervention before the occurrence of an unplanned shutdown.

The graphic below shows other helpful features.

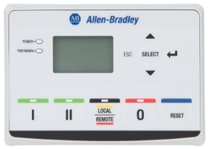

NFPA70E Arc Flash Considerations

The E300 electronic overload relay can help protect your people from arc flash hazards. Utilizing the door-mounted operator stations, you can reset trips without having to open the panel. Operator stations also allow control of the motor right from the panel if you desire. There are versions of the operator stations with a diagnostic display as well (shown on the right).

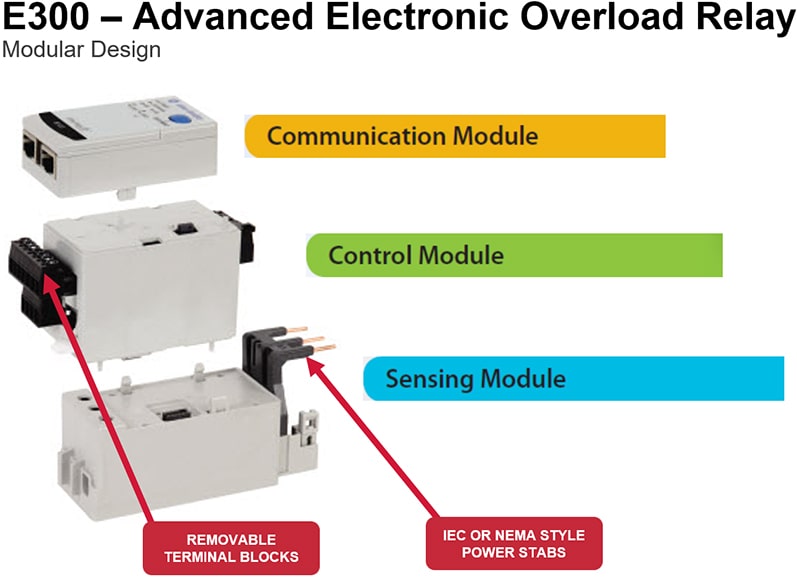

E300 Electronic Overload Relay Ease of Use

All information is collected either through Ethernet or DeviceNet. There is an “add on profile” in RSLogix™ software to make programming simple. Control voltages can be 24VDC, 120VAC, or 240VAC. When it is time to replace a module, the E300 electronic overload relay has automatic device configuration (ADC) capability. Just plug in a new device, the system will recognize it and upload all the parameters.

Modularity

The E300 electronic overload relay is a modular device, so if you decide to make some changes in what you want to monitor, modules can easily be swapped. The “control module” allows you to add additional local I/O to your network as well.

We Can Help You Realize the Power of Motor Diagnostics

You are already using motor overloads. Why not upgrade to a full-featured device that will make your life easier. You can improve your preventative maintenance program AND by collecting motor data have better visualization of your production status and energy usage. If you would like to know more about the E300 electronic overload relay, contact us today!

All diagrams and product images are © Rockwell Automation