Blog > Automation > 3 Easy Steps to Using FactoryTalk Edge Gateway

3 Easy Steps to Using FactoryTalk Edge Gateway

9/28/21 | David Kew, Rexel Technical Consultant

Blog > Automation > 3 Easy Steps to Using FactoryTalk Edge Gateway

9/28/21 | David Kew, Rexel Technical Consultant

In this blog, I will walk you through three easy steps to get you started with FactoryTalk® Edge Gateway™ software in your facility. But first, let’s look at why you should consider implementing this software to connect your manufacturing data to information systems.

To stay competitive in today’s rapidly changing marketplace, manufacturers need fast access to intelligent, actionable operational data. The good news is that the volume of data coming from manufacturing equipment over the last decade has exploded. Unfortunately, this data is not always organized in a meaningful way and can be located across systems that aren’t connected.

To make this information more useful to non-automation engineers, it needs to be managed in a well-defined and structured data model that is organized using an easy-to-understand hierarchy rather than the tag or I/O based structure typically implemented in automation systems. Data that is formatted in a logical model can be used by data scientists to create a reporting system that will help company decision-makers steer the company forward in a profitable way.

So, where does this leave us? We know that manufacturing systems have more data available than they ever have. The automation engineers that build these machines understand the processes and the context for this data, but they don’t build or control the IIOT systems company management looks at every day. We also know that data scientists and IT groups do build the IIOT systems management uses to make decisions, but they don’t understand the context of the data that is available from the manufacturing equipment.

FactoryTalk Edge Gateway software provides an easy way for automation engineers to create a data model to connect and synchronize data from machines to IIOT systems. It doesn’t store data long term but creates a data model and connects the data to applications such as a SQL database, ThingWorx, or Microsoft® Azure.

Here is the three-step process to make it happen.

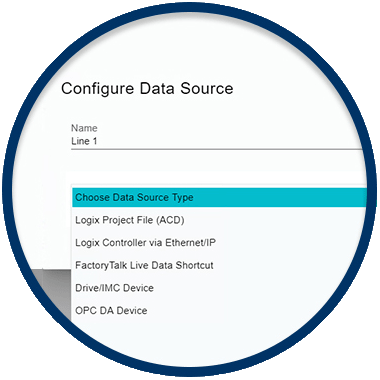

Connect to data sources such as FactoryTalk Live Data, Ethernet/IP, Kepware®, and FactoryTalk Smart Objects. We estimate a 30%-time savings using FactoryTalk Edge Gateway vs connecting to each application individually, analyzing the data, and selecting the correct tags.

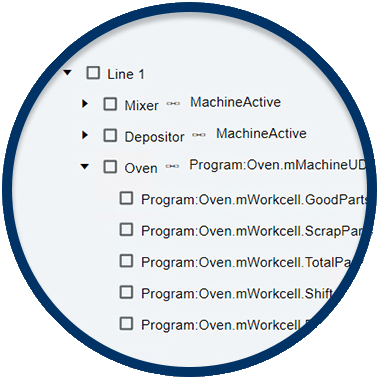

Contextualize the data by using the simple interface in FactoryTalk Edge Gateway to build a data model. We estimate a 50% savings vs creating unique models in different IIOT platforms.

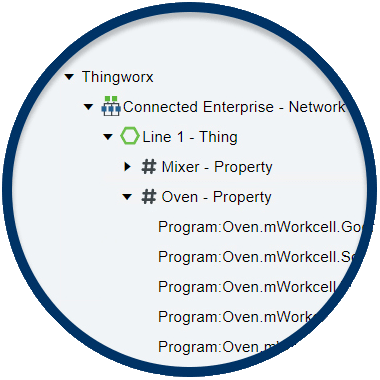

Connect your data model to your IIOT platform or data store (e.g., SQL, Azure, ThingWorx). Because the model exists in FactoryTalk Edge Gateway, if you switch to a different IIOT platform in the future, or add an additional platform, there is no need to rebuild the model. This can lead to significant time savings.

Once this contextualized data is available to ThingWorx, Azure, or another IIOT platform, it can be enriched with data from other plant systems. For instance, the ability to see that every time the plant has a power dip, a manufacturing line jams could lead to increased production uptime by adding a DySC® system or UPS to the manufacturing line.

FactoryTalk Edge Gateway provides a configurable common information model that can be mapped to on-premises or cloud-based applications for easier consumption. Three easy steps allow everyone from the shop floor to the top floor to make smarter decisions.

We Can Help!

From making the most of your data to getting you started on your digital transformation, we can help! Our Automation Specialists are here to offer expert advice. Contact us today!