Blog > Automation > Light Curtain or Laser Zone Scanner?

Light Curtain or Laser Zone Scanner?

4/7/20 | Tom Hopkins, Rexel Technical Consultant

Optical Presence Sensing

When customers call me, they don’t always ask the right questions. Instead of asking things like: “Optical presence sensing safety devices, what should I use?” “How do I know the best way to apply it?” or even “Do I need a light curtain or a laser zone scanner?” Instead, they simply say:

“I need a light curtain.”

I get this call frequently, and my response is always the same. “You do? What are you trying to accomplish?” A light curtain is a great safety device WHEN it is applied correctly. It’s always important to consider the application carefully. Be aware there are OTHER types of optical presence sensing safety devices, as well. Depending on the application, a safety laser zone scanner could be a better choice.

Light Curtain Review

Before we look at the laser zone scanner as an alternative, let’s revisit light curtains (LC). As you probably know, an LC is an array of light beams. One stick of the LC contains the transmitters and the other receivers. If an object blocks any beam in the array, the LC will drop its signal and the machine controls will go to a “safe state.”

PARTIAL BODY ACCESS

If personnel can reach into a dangerous area, an LC is a good option to consider. Hazards where a reach-in can cause arms, hands, or fingers to be exposed are classified as partial body access. Think about a press machine as an example. If the operator has a fleeting moment of inattention, it could be a very bad day.

APPLICATION CONSIDERATIONS

- Beam Spacing: Beam spacing for finger detection is set at 14 mm. LCs designed to detect hands or larger objects have a beam spacing of 30 mm. If the LC is close to a hazard, and you don’t want a finger to squeeze through, you’ll want to use the closer beam spacing. Additionally, closer beam spacing will impact the calculation below.

- Where to Place the LC - Safe Distance Calculation: This is probably the most frequent misapplication of an LC. You need to perform a “safe distance calculation.” Don’t worry, there are standards to guide you. In the USA, look to these two standards; ANSI B11.19 and ANSI RIA R15.06. Another excellent resource is a Rockwell Automation® “Safebook” publication. It covers all things related to machine safety controls, including safe distance calculations.

SAFE DISTANCE CALCULATION OVERVIEW

Consider how quickly the machine will stop once triggered to do so. How far can body parts penetrate past the LC and into harm’s way before the hazard completely stops? The standards set a speed of 63 inches per second when considering the speed of a body part.

The official formula is Ds = (K x T) + Dpf.

Where:

Ds = The minimum safe distance from the hazard.

K = The 63” per second speed constant of a body part.

T = The overall stopping time of the system, from the initiation of the stop signal to the cessation of the hazard. This is a totalized number that includes the response time of the LC, the control circuit, and the machine component stop time.

Dpf = Depth penetration factor. This is determined by the beam spacing of your LC.

FULL BODY ACCESS

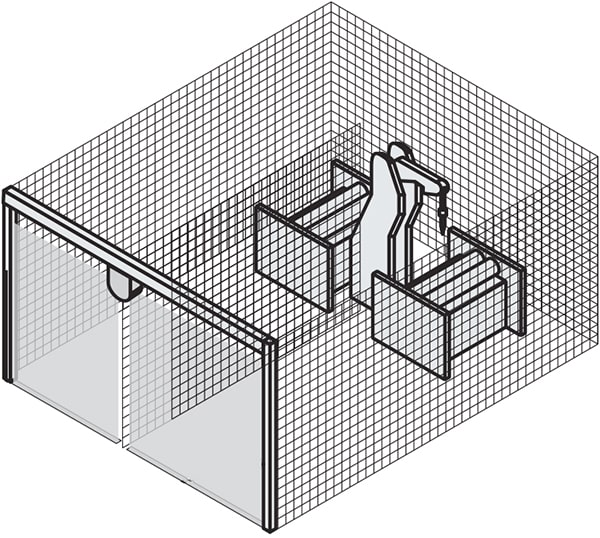

An LC will only protect workers if an object is in the plane between the transmitter and receiver. What about an application where a person can walk through the LC? For example, a robot cell. Can an operator go through the curtain plane and be vulnerable to a restart situation on the other side? Of course, you can set up your controls so that the machine will stop as soon as a person crosses the plane of the LC and require a manual restart of the machine. But what if another person pushes the start button while the operator is still in the hazardous area? How do you POSITIVELY confirm there is nobody in the space before a restart?

This is where you want to consider a laser zone scanner.

Laser Zone Scanner

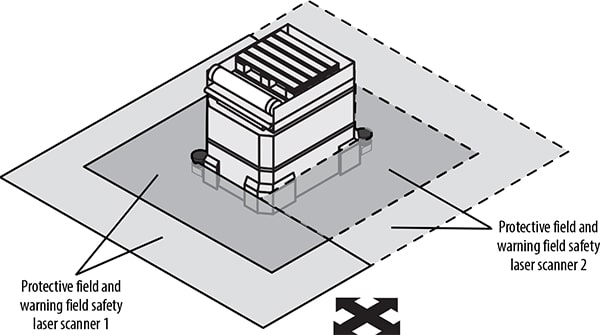

I like to call a laser zone scanner an ankle scanner. It’s programmed to look at the area and make sure there is no one standing in harm’s way. Think of a safety pressure mat, but it is a non-contact device. The area of concern can be programmed in any size or shape.

ADVANTAGES AND BENEFITS OF A LASER ZONE SCANNER

- Warning Field: You can program a warning field in front of the protected field to reduce accidental incursions.

- Single Component Device: There is no need to align anything as it is a single component device.

- Light Curtain Replacement: You can use a laser zone scanner as an LC replacement if it’s hung from the ceiling and pointed to the floor. This is handy in applications where lift trucks tend to bump and misalign an LC.

- Moving Hazard Attachment: A laser zone scanner can be attached to a moving hazard to stop a collision or protect a pinch point.

Optical Safety Devices Limitations

In applications where there is dust or steam, you may want to consider another solution. Any condition that will block or bend light will cause issues with an optical sensor.

ADDITIONAL INFORMATION:

- B11.19 Standard

- ANSI RIA 15.06 Standard

- Rockwell Automation Light Curtains

- Rockwell Automation Laser Scanners

We Can Help You Make the Best Choice

Our Automation Specialists are machine safety and sensor experts. We're here to help you evaluate your needs and the right optical safety devices to protect your workers. Contact us today!

All images are © Rockwell Automation