Blog > Automation > Lockout/Tagout Requirements Made Easy

Lockout/Tagout Requirements Made Easy

10/12/21 | Michael Martinson, Rexel Technical Consultant

Blog > Automation > Lockout/Tagout Requirements Made Easy

10/12/21 | Michael Martinson, Rexel Technical Consultant

Whether you’re an end-user, OEM, or machine builder, lockout/tagout requirements are something we all must think about. Choosing the right firm to partner with when it comes to keeping people safe can be a nerve-racking process.

Finding that balance of safety and productivity can be daunting for any safety manager. Whether it’s planned preventative maintenance or when something goes bump in the night, production and maintenance personnel demand quick, safe access to machines to keep finished goods flowing. Part of their job is to meet lockout/tagout requirements to protect workers, ensuring they return home at the end of each shift. By partnering with Rockwell Automation®, keeping people safe and production humming is exactly what you’ll get. Crazy? Not at all, let me explain by showing you a few options to consider.

To help you meet lockout/tagout requirements, Rockwell Automation engineers start by conducting a remote audit of the facility's existing program and employee training plan. This is a great way to have the assurance that your existing lockout/tagout program is up to date, functional, and safe.

You can expect the following upon project completion:

- Sample audit of procedures

- Plant assessment

- Remote review of written training program and audit records

- Action plan with recommended improvements

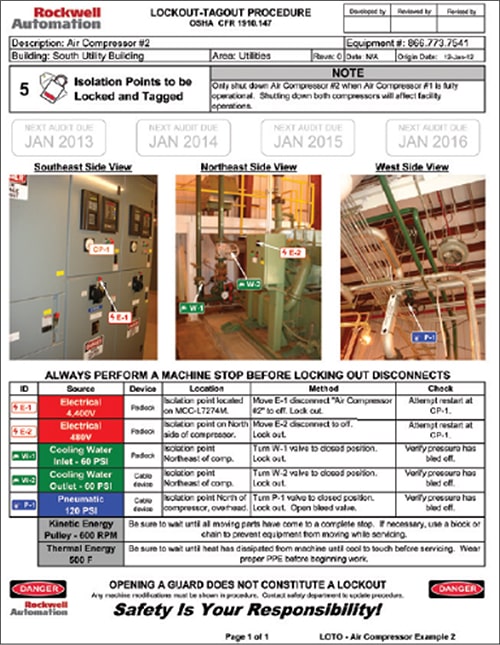

This solution empowers our customers by providing the necessary knowledge, templates, training, and tools needed to help you meet lockout/tagout requirements. Think of it as training wheels, as our Rockwell Automation Safety Consultants work side by side with our customers to achieve and maintain compliance with OSHA standard 29 CFR 1910.147—all with the convenience of complete remote delivery. You will be able to develop procedures with in-house resources. This package includes the following:

- Remote lockout/tagout consultation provided by a Rockwell Automation subject matter expert

o Template – Rockwell Automation standard procedure template in compliance with the lockout/tagout requirements (including CFR 1910.147)

o Training – Education on regulatory compliance and procedure creation

o Tools – Guidance on procedure creation and program management

o Address any of your questions and concerns

- Rockwell Automation will assist customers in gathering data and developing up to ten Type 1 LOTO procedures

- Ongoing Program Support

o Additional remote support to ensure you are properly equipped and enabled to complete their program and meet lockout/tagout requirements

o Three one-hour follow-up meetings to be scheduled at one, three, and six months after the initial consultation

Our full package is designed for facilities that need a program implemented by the subject matter experts to ensure it meets lockout/tagout requirements, which you can eventually take over and own the program moving forward. We provide the following based on your total number of procedures:

- Standard isolation point tags, which are injection molded

- Installation of the standard isolation point tags and laminated lockout procedures

- Copies of each lockout/tagout procedure are provided in the following formats:

o One laminated copy – laminate options: slotted, hole-punched

o Digital copy in Microsoft Excel format

- Lockout/tagout device and hardware list

o A comprehensive list of the lockout/tagout devices and hardware needed based on the specific needs of the facility and equipment.

- Policy Review

o A Rockwell Automation engineer will review your current lockout/tagout policy and provide a list of recommended updates if needed for compliance with the lockout/tagout requirements (including CFR 1910.147)

- USB Flash Drive

o Includes digital copies of procedures, training materials, or any other information relevant to the hazardous energy control program

- Training Services

o Training included covering authorized employees, affected employees, and/or program management training modules

Whether your company needs a sanity check on your existing program or just a little extra help from our experts to a full turnkey lockout/tagout program, Rockwell Automation and Rexel can put a plan in place to help you achieve your goals. Contact us today!