Blog > Automation > Methods for Machine Safety & Access Control That Work Together

Methods for Machine Safety & Access Control That Work Together

5/5/22 | Will Cole, Rexel Technical Consultant

Blog > Automation > Methods for Machine Safety & Access Control That Work Together

5/5/22 | Will Cole, Rexel Technical Consultant

Safety of personnel is key in manufacturing facilities. There are many ways to protect your people from hazards. This post will delve into one specific way: using trapped key interlocks and access/control locking modules. If you have the need for full body access control in areas of your plant, this post is for you.

Machine safety is an important topic whenever you have moving hazards like motors, conveyors, actuators, and robots. This topic falls under the “Automation” world of Horizon Solutions®, and we will use Rockwell Automation® products for discussion purposes. What we will cover:

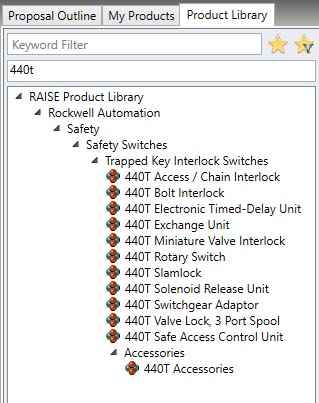

1) 440T Trapped Key Interlock Devices

2) 442G Multifunctional Access Box (or, as we’ll refer to it, MAB)

3) And how they can “play nicely together”

Trapped keys are a safety device used to limit who enters certain areas and how. They are based on the simple and practical premise of “A key cannot be in two places at once”. Trapped Key Interlock Switches allow access to hazardous areas only when an appropriate key is inserted into the interlock. A safe sequence of operations is enabled through transfer of keys. This is but one element of overall machine safety.

A term to discuss is “sequential access control application”. Also known as sequence of operation. This will indicate how a person on the plant floor should de-energize the machine, how they use the keys, and then how then return the keys, and restart the machine. This process is a key element of the overall plant and personnel safety.

This post will focus on the 440T family from Rockwell Automation. Typically, a Trapped Key Safety device will consist of a robust (heavy duty) housing, plus a lock cylinder, plus a sliding bolt. This family covers quite a bit of breadth and depth. There are valve locks, solenoid release, rotary, chains, bolts and many more.

For sequencing, there are some options, typically involving using one key to release the “trapped key” from the switch body. Without that key in position, the machine cannot be restarted. The maintenance or engineering person will then keep the Key on their person while inside the machine and/or hazardous area. Just to get the conversation started, we’re going to use a 440T-MRKSE110A type single key rotary switch.

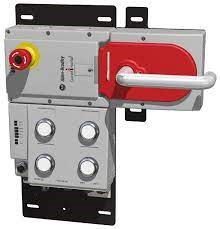

The 442G Multifunctional Access Box (MAB) is a device used for guard locking and access control within an automated system. You’ll typically see MAB units wherever you see access doors. I tend to think of them as synonymous with yellow and black metal wire mesh fencing like this at WireCrafters.

A typical machine or robot cell will be guarded with wire fencing on all or most sides. A plant worker may enter and exit that area for routine maintenance, or to clear jams, or similar work. In some cases, the worker will need access every hour, sometimes once every 8-hour shift, or sometimes less frequently. Say, only once or twice a week. It depends on your application.

The types of cells we are talking about are often just one cell of many in a linear operation of some sort. Remember, the machine safety of that total operation is only as good as its weakest link. We want good safety throughout. Top to bottom, start to finish. This post talks about MAB style handles and Trapped Key Switches. We would expect most machines to also have E-Stop buttons, door switches, perhaps some light curtains, and maybe cable pulls.

Note: MAB devices aren’t necessarily linked to Trapped Key Switches, per say. Trapped Key Switches are not required with MAB applications. Either can be a safety device on its own. Section 3 of this post shows how they can work well together. That is the advanced part of the post.

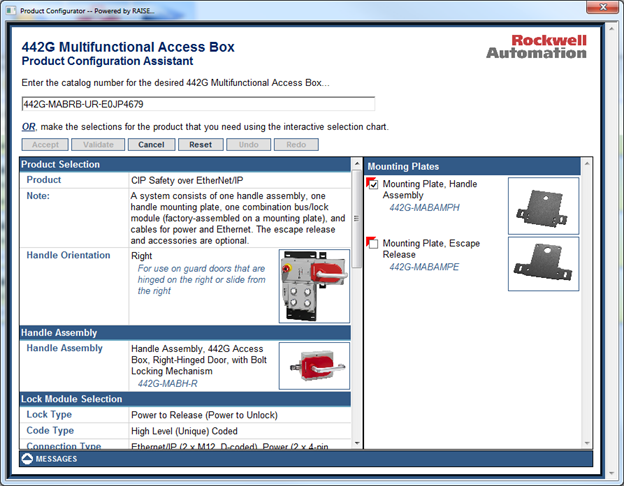

To keep the example going, assume you want to use a RH, PTR device. You can arrive at 442G-MABRB-UR-E0JP4679. Full description includes Right-Hand handle orientation, + CIP Safety over EtherNet/IP, + Power-To-Release (PTR). Power-To-Release is also known as (Power to Unlock). The base module has x1 E-Stop and x4 Push Buttons. These push buttons are configurable as far as lens color and function.

We’ve also accounted for basic accessories like 442G-MABH-R (the handle assembly), 442G-MABE1 (escape release), and 442G-MABAMPH (mountain plate).

This section is an advanced technical exploration of machine safety. So, you have a 440T device and a 442G device. They control how workers enter the hazardous area. Both are used on the same door in the same area. How do we make them play nicely together? Rockwell Automation has already done the heavy lifting with Publication SAFETY-AT186A-EN-P - June 2021. That document is a safety function application technique. It explains how to wire, configure, and program a 442G Multifunction Access Box (MAB) with CIP Safety to monitor a 440T Rotary Trapped Key interlock switch to control a power-to-release door.

The full document is 26 pages long and assumes you are using a Compact GuardLogix (5069-L3100ERMS2) controller, but you can substitute a GuardLogix controller that supports the safety rating that is demonstrated in this safety function application technique.

Essentially, it guides you through how the 442G MAB locks and monitors access to the hazardous area. If the door is opened or unlocked, or a fault is detected in the safety function, I/O safety modules de-energize and monitor a redundant pair of 100S-C contactors.

Sample project files (AutoCAD, EPLAN, ACD, SISTEMA, and Verification and Validation checklist) are included to help you implement this safety function. Interested in further safety function application documents? The full library can be found here:

This section was a deep technical dive. Rockwell Automation provides content and support for similar applications.

This post provided some detail on just a few methods for Machine Safety and for Access Control. The 440T trapped key family is a good solution for sequential control when allowing access to hazardous areas. The 442G MAB family is a good solution for door locking and additional access control. When they work together, safety doesn’t have to come at the expense of productivity. Safety can help improve your efficiency. If you have challenging or advanced safety applications, your local Horizon Solutions Automation Specialist can help guide you. Reach out to our team today.