Blog > Automation > The Advantages of Photoelectric Sensors

The Advantages of Photoelectric Sensors

1/3/19 | Robert Serano, Rexel Technical Consultant

Blog > Automation > The Advantages of Photoelectric Sensors

1/3/19 | Robert Serano, Rexel Technical Consultant

Recently, a customer called me because he was having issues with his press machine. The limit switch was no longer sensing when a material was present, and so the machine was not initiating the press to punch. This was not the first time he had run into this wear-and-tear related issue, so he was looking for another solution. I recommended that he consider upgrading to a photosensor.

A type of proximity sensor, these sensors can detect the distance, absence, or presence of an object by using a light transmitter, making them an ideal alternative to inductive proximity sensors. And looking at this customer’s issue specifically, whereas a limit switch requires objects to come in contact with it, a photoelectric sensor only needs an object to pass through its light field, blocking its beam’s transmission.

There are three primary types of photoelectric sensors: proximity sensing (diffused), retroreflective, and opposed (through beam). Each has its advantages, depending on use case.

Photoelectric technology allows for long- and short-range detection and can detect almost any material, including glass, metal, plastic, wood, and liquid. Their sensing distance ranges surpass inductive, capacitive, magnetic, and ultrasonic technologies by significant margins. And their small size makes these sensors a great fit for almost any application.

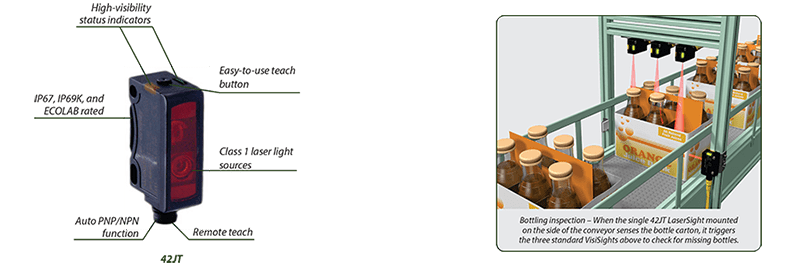

Additionally, when compared to limit switches, photo sensors don’t have moving parts or require contact, limiting wear-and-tear over time. For this customer’s press machine, I recommended the VisiSight Laser 42JT series from Rockwell Automation®, which is a part of the IO-Link sensor portfolio.

Laser sensors have better operating margins and sensing distances than LED-based photoelectric sensors, allowing them to detect smaller objects in narrower fields. The 42JT series offers a wide range of sensing modes, simplified sensitivity adjustment, and light vs. dark output selection. This family of sensors continuously monitors load connections and automatically configures output, making them easy to apply.

We know that when it comes to automation, good, better, and best are relative to your unique needs. Let us help you find the right solution. Our experienced Automation Specialists are on hand offer guidance and support. Contact us today!