Blog > Automation > PowerFlex 755TS: Revolutionizing AC Drives for Greater Performance

PowerFlex 755TS: Revolutionizing AC Drives for Greater Performance

1/10/24 | Scott Savage, Senior Power Technical Consultant

Welcome to the next generation of PowerFlex 750 Drives – The PowerFlex 755TS variable frequency drive (VFD). These drives are designed to deliver greater output, uptime, energy savings, and productivity. The PowerFlex 755TS will eventually replace the PowerFlex 753 and PowerFlex 755 Classic.

Please keep in mind the same options modules fit in the PowerFlex 753TS and PowerFlex 755TS. This classic drive has had a great run, but now we are turning to better technology to provide things you have asked for over the past few years. We listened, thought about it, and solved some of the challenges in the marketplace to improve everyone’s experience.

Now, the drive of the future has arrived. This blog post will cover some key features of the new drive that can apply to most six-pulse applications in the field today!

Although we will not be covering the component drive future offering in this post, there have been exciting developments in the PowerFlex 520 arena, so stay tuned and ask your Rexel Power Specialist to give you a glimpse into the immediate future.

For now, let’s look under the hood at the PowerFlex 750 offering that is available in the lower and higher horsepower.

TotalFORCE® Technology combines high-performance motor control, advanced self-monitoring capabilities, and a contemporary digital platform to deliver faster, more precise, and more responsive AC drives.

Common Industrial Protocol (CIP™) Security is an open-standard secure communication protocol developed by ODVA for EtherNet/IP™ communications, providing the final layer of defense against malicious communication attacks commonly carried out over large organizational networks.

The PowerFlex 755TS can be used as a speed regulator (80% of most applications), reducing speed to the proper setpoint, and saving significant energy over time. It’s commonly used in V/hz or Sensorless Vector Mode (V/hz with a world-class auto-boosting algorithm).

The PowerFlex 755TS can also be run in torque regulation mode using Flux Vector with TotalFORCE technology. The high bandwidth and algorithms for special applications make this a superior choice for web applications, vertical applications such as cranes (anti sway algorithm), or torque control while load sharing with another drive on the same mechanical system. In this case, one drive would run in speed regulation (producer) and the following drive would run in torque control and consume the torque reference from the producer. The follower matches torque, and speed becomes the secondary control loop.

The PowerFlex 755TS offers up Position Control with CIP (direct backplane control from a Logix Controller). This is a feature the PowerFlex 753TS will not have available. Electronic line shaft applications, especially large induction motors beyond a servo motor size for rotation and back and forth applications, are good examples for this type of control. These do not replace motion pick and place applications. This would be a Kinetix solution (limited in size due to PM motor design for servo style motors).

The PowerFlex 755TS drives induction, PM outer & inner magnet designs, and reluctant synchronous motors (not synchronous motors that require brush design).

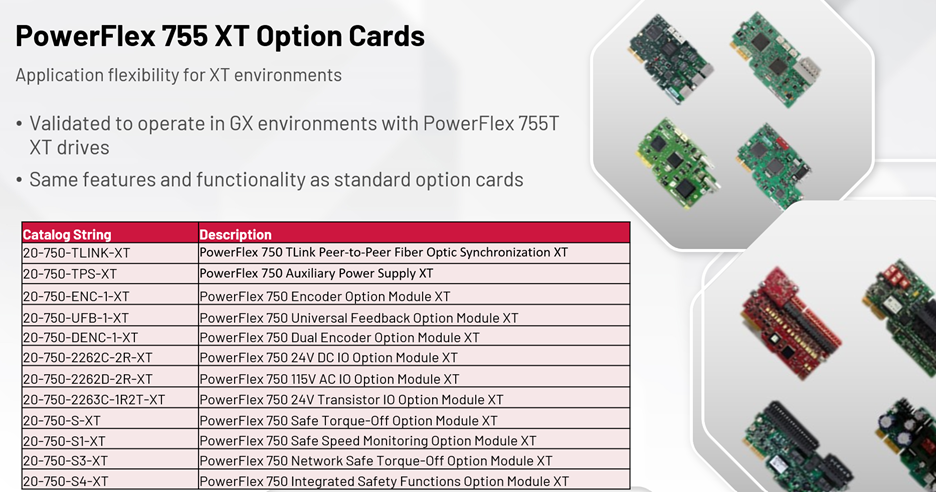

XT design is an option in the PowerFlex 755TS for corrosion resistance – not only the printed circuit boards, but also the power components as well.

The unique level of CIP Security is the best feature of all! Identification tokens and handshaking is done with FactoryTalk Security systems and Stratix switch technology to prevent threat actors from manipulating parameter structure. Consider this a guardian approach on the power side of our business. Yes, they can infect ethernet switches and drive firmware if they have the skillset. So, many have questioned why the FactoryTalk platform needs to be installed before configuration software could be added (security for one) and the present platform allows this to happen with V34 in Logix controllers.

Please contact us for more information on this added protection. Rockwell Automation also has trained service engineers to help implement these security systems.

Finally, the “T” is TotalFORCE technology, so what is the difference between the other “T” drives? The PowerFlex 755TS is a 6-pulse drive.

Active Switching Drive Systems, Not Six-Pulse Drives

The PowerFlex 755TL drive is a low-harmonic drive commonly used in pollution control and water quality markets to exceed IEEE 519 harmonic content requirement (less than 5% distortion of incoming waveform from utility at point of common coupling. Low regeneration capabilities – approximately 20%).

The PowerFlex 755TR drive is a complete regenerative drive commonly used in heavy inertia applications or vertical applications to avoid large regenerative power on the DC Bus of a drive. Please do not consider this a device to generate power and receive a rapid payback. Yes, it reduces wasted power that might bleed off with a braking resistor.

The PowerFlex 755TM drive is a low-harmonic drive commonly used for a common bus application, there is a common Active Front End (AFE) that feeds or receives power to many drives with no bridges (rectifiers) on the drive themselves. DC power is fed to each drive from the AFE and regens back on to the common bus to each drive and AFE. When too much power is generated on a slowdown of the system, excess power is generated back on to the AFE and is reused by the electrical distribution system.

Six-Pulse Drive Architecture

The House has New Mansions?

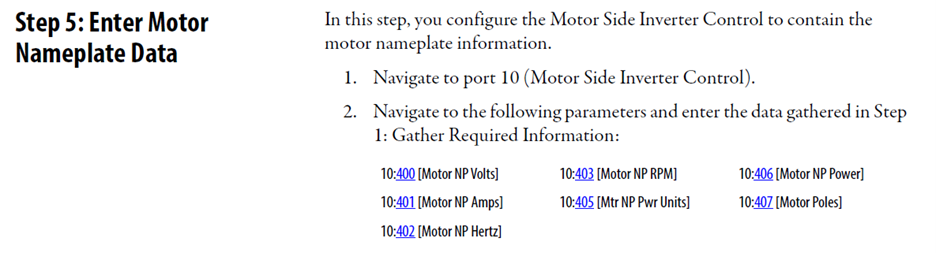

Hint: Inside port 10 holds many parameters that used to be in port 0 on the PowerFlex 750 Classic.

Hint: Inside port 10 holds many parameters that used to be in port 0 on the PowerFlex 750 Classic.

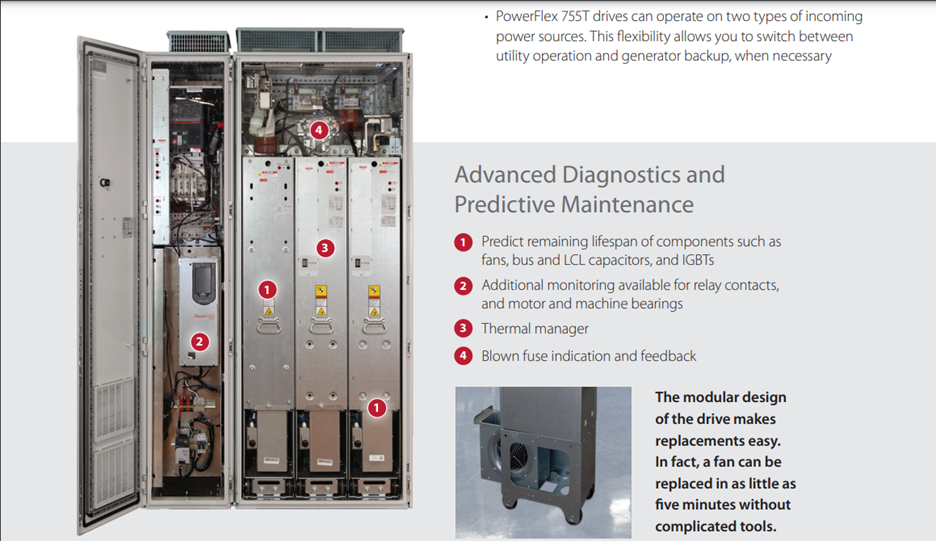

Predictive Maintenance Analytics

Reduce downtime, increase production efficiency, and optimize skilled personnel with a predictive approach to maintenance. The graphical interface in Connected Components Workbench and Studio 5000 Logix Designer reports real-time information.

Migration

PowerFlex 755TS unit dimensions, cable positioning, and the user interface are the same as the PowerFlex 753 and 755 drives, and software conversion tool is available to optimize parameter alignment when migrating from other PowerFlex 7-series drives.

Technician Value

Predictive maintenance provides the remaining life of key components, shifting downtime risk away from the technician. Installation and retrofitting are easy with the same mounting hold pattern and wiring positions, and there’s a common technology platform across 755T and 6000T that minimizes training needs. Additionally, adaptive control reduces the need for advanced tuning skills, resulting in optimized drive performance.

Automatic Diagnostics and PowerFlex Drives (Logix v34)

Access and display diagnostic information without additional programming.

Overview

Diagnostics are automatically created for all devices in the IO tree. What’s more, FTAE provides both real-time and historic diagnostic information, and the FTView SE AD frame is automatically populated with device diagnostic events.

Benefits

- No more programming through alarms to get and display diagnostic information

- Provide contextual information from the Logix Project with the diagnostic event

- PowerFlex 523/525, 753/755, 755T support basic fault and alarm notifications

Advanced Diagnostic Parameters in Port 12

Corrosion Protection for Power Components (XT Options)

Protection From Corrosive Environments

Reduce the threat of early equipment failure from corrosion with PowerFlex drives with XT corrosive gas protection.

- Industry leader in research and development for corrosive environments

- Advanced design guidelines, installation guidance, and hardened solutions

- First and proprietary corrosion test protocol to help improve uptime and productivity

- Reduce corrosion-related downtime in your corrosive gas environments

- Ideal for environments where H2S, SO2, and chlorine gas are present

Reduce Corrosion-Related Downtime

- Reduce unscheduled downtime in corrosive environments

- Reduced installation footprint for corrosive solutions

-

Reduce costs due to reactive maintenance

- Improved component design and selection

- Enhanced corrosion-related coatings

- Critical connection point protection

- Standard product offering

- Validated to exceed GA (ISA) and CX (IEC) in accelerated corrosive environment tests

Option for PowerFlex 755TS drives. Standard on PowerFlex 755TL, TR, and TM drives.

CIP Security

Reduce the Risk of Cyberattacks

Increase security for your smart machines, network, and manufacturing equipment.

CIP Security-enabled devices, like PowerFlex 755T drives, improve the security of your plant and minimize the risk of cyber incidents. CIP security provides an encrypted secure transport layer in an EtherNet/IP network to help protect the drives from malicious communications. CIP Security provides:

- Authentication to help prevent unauthorized devices from establishing communications

- Integrity to help prevent tampering or modification of communications

- Encryption to help prevent disclosure of data

Adaptive Control

The PowerFlex 755TS includes adaptive tuning that can identify harmful machine resonances and suppress the output of the drive from exciting those vibrations.

Adaptive Control is a key component of TotalFORCE Technology. As your equipment operates, Adaptive Tuning, Load Observer, and Bus Observer can monitor machine characteristics that can change over time and automatically compensate for the changes that occur. This advanced self-monitoring capability helps reduce commissioning time and mechanical wear while improving uptime.

TotalFORCE Technology combines high-performance motor control, advanced self-monitoring capabilities, and a contemporary digital platform to deliver faster, more precise, and responsive AC drives.

Adaptive Tuning

Adaptive tuning helps increase machine reliability and performance.

- Monitors real-time drive and system performance characteristics and adapts if necessary

- Tracking notch filters automatically identify and supress potentially harmful resonance and vibration conditions. With four tracking noth filters, the PowerFlex 755T drives are able to identify up to four system resonant conditions simultaneously

- Can be used to indicate the need for maintenance and machine wear over time

Load Observer

Load observer reduces startup time by reducing the effort needed for tuning.

- Automatically monitors and compensates for changes in inertia and for motor-to-load compliance by anticipating needs for torque

- Continuously compensates for normal machine wear, including bearings and couplings

- Provides consistent dynamic behavior

Bus Observer

Bus observer helps increase reliability by dynamically controlling voltage.

- Compensates for changes in demand on the DC bus

- Adjusts current control to help improve management of the DC bus voltage

- Allows for lower tuning gains in the voltage and current regulators to help prevent electrical system resonance that can occur when the initial drive tuning is too aggressive

- Reduces startup time needed for tuning

Illustration shows a combination of Adaptive Tuning and Load Observer in a motor control application.

Frame Eight and Above Roll Out Design

Thank you for taking the time to learn about and share the new drive products from Rockwell Automation. The manuals for the PowerFlex the 753TS and PF755 are:

Be safe and happy programming! Want to learn more? Contact the experts at Rexel today!