Blog > Automation > Unexplained Downtime? It Could Be PQ Issues

Unexplained Downtime? It Could Be PQ Issues

12/1/21 | Tom Hopkins, Rexel Technical Consultant

Blog > Automation > Unexplained Downtime? It Could Be PQ Issues

12/1/21 | Tom Hopkins, Rexel Technical Consultant

Are you having intermittent issues with your machines? Are things shutting down for no apparent reason, or strange glitches popping up at seemingly random times? You could be having PQ issues (power quality issues).

My first question is always, “Have you tested your power quality?” Yup, power quality can have a big impact on reliability, and your equipment may be more sensitive than you may realize.

Let’s look at various sources of PQ issues.

Most people say, “No way! The utility gives us high uptime, and we don’t have any issues.” Yes, the utility gives you high uptime, but are you SURE about the quality of the power supplied?

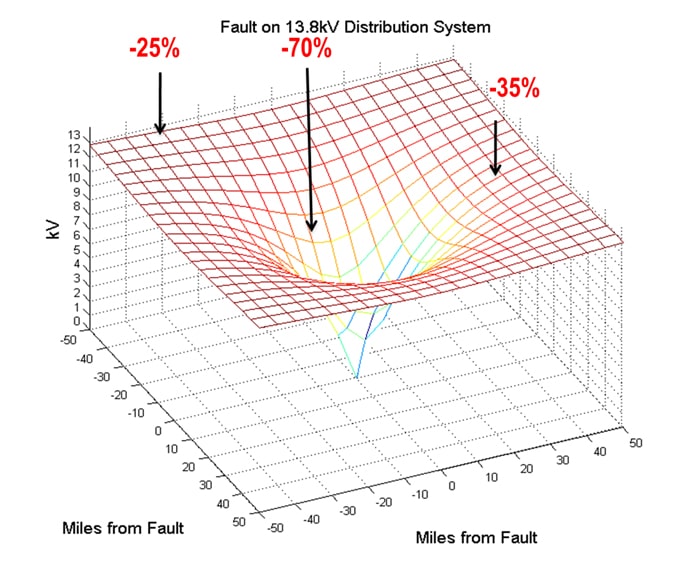

Let’s talk real-world events. Consider a squirrel becoming a conductor to ground on a high voltage line 30 miles away from you or a car hitting a utility pole. We are all familiar that these events happen, but I bet you didn’t know that a short duration fault will send a ripple through the power distribution system for a long distance. Look at the below diagram showing what happens on the grid when a fault occurs. It covers a longer range than most people realize.

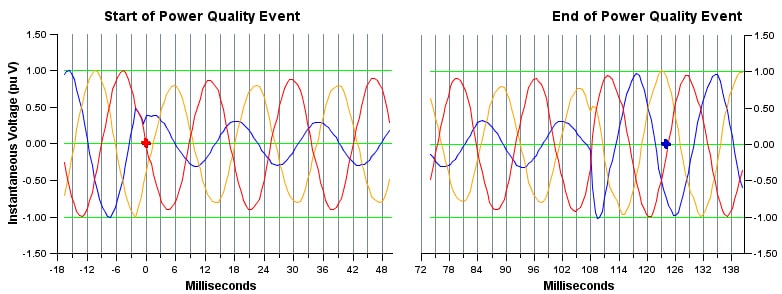

The EPRI (Electrical Power Research Institute) did a study that monitored 300 sites for over two years. They found 96% of all PQ issues were voltage sags less than two seconds, and the majority of those were under 200 milliseconds. You certainly won’t detect these events without measuring equipment. But your power supplies, relays, and controllers may react adversely to a deep quick voltage sag. Switched-mode power supplies are especially sensitive to quick voltage changes. Have you noticed power supplies popping off? Relays and other controls may drop out due to sags, causing your machine to have phantom stoppages or worse.

It is believed that voltage sags have the greatest impact on productivity at automated sites and are responsible for 10-30% of unplanned downtime each year.

Just a few items in your plant that could be creating PQ issues:

- Motors switching on/off causing voltage sags and surges.

- Motor drives causing noise and harmonics.

o Are your drives grounded correctly, or is that noise going through the plant wiring?

- Operation of fuses and circuit protection.

- Operation of welders.

- Power factor correction capacitor banks.

I got a call from a good customer complaining about inductive proximities faulting in a location. Initially, their response was, “These proxes you are selling me are cheap and unreliable.” The issue was intermittent, causing headaches.

As they described the issue to me and the flashing pattern on the proximity output LED, I could tell the proximity was responding to a surge and protecting itself. So, we placed a surge suppressor in the trouble location. PQ issues solved—the proximities didn’t fault anymore. What we came to realize was another piece of equipment on the same power branch was creating spikes.

This type of thing is more common than you might expect. Back in the day, components were more rugged and could handle PQ issues. Now circuit boards are a lot smaller and the gap between transistors is minuscule (i.e., it doesn’t take much to fry a circuit board).

How can you solve a problem if you cannot see what is causing it? Let’s figure it out, and if it’s PQ issues, there are products to mitigate them.

Let’s see what tools you have available to diagnose your problems.

Rockwell Automation® sells a product called an i-Sense® voltage monitor. This product will highlight and timestamp events coming into your plant. You can then correlate to downtime. Additionally, the system will compare to other meters on the grid to confirm there was a grid event.

The PowerMonitor™ 5000 unit has three available versions for identifying everything from sags and surges to harmonics and transients. Some versions will even give you a waveform capture. And this device can be connected to your RSLogix™ software-based PLC controller to trend, time stamp, and more.

Once you know what you have going on, there are many products to combat PQ issues, including:

Give us a call to help navigate which is best for your application. Contact us today!