Blog > Automation > Sleep Better with a Process Controller

Sleep Better with a Process Controller

1/18/22 | Marcia Pohl, Rexel Technical Consultant

Blog > Automation > Sleep Better with a Process Controller

1/18/22 | Marcia Pohl, Rexel Technical Consultant

Your head is just sinking into your soft pillow and all the problems from the day are drifting away when suddenly your phone goes off. At first, you try to ignore it, but you know you can’t. You roll over to check your messages to find that the plant is down again. Knowing that you are the only one that can effectively determine why no product is going out the door, you drag yourself out of bed. If you are lucky, you grab your laptop and VPN into the system to look; if you’re not, you get dressed, get into your car, and drive back to work. So many of us have found ourselves in this situation, and believe me, it is not fun. People may tell you, being the only one that can fix the plant is great job security but every time the plant goes down, it reduces the overall profit, and that can put everyone’s job as risk.

How do you set up a system where operations and maintenance staff have the resources to determine what is going on when the process goes down? Education is an important key to this; operations need to know the flow from raw materials to finished goods while understanding the standard operation procedures (SOPs). The next step is to design a control system that allows users to easily see the current state of the system not only when things are working, but also when something goes wrong.

The new process controllers from Rockwell Automation® can also help everyone see what is happening in the process. The PLC no longer has to be considered a black box that only the sleeping control engineer can understand. There are many features that have been added for engineering, maintenance, and operations that help balance the challenges that manufacturers face today.

The process PLC has been made more configurable rather than programmable allowing more people to develop the system. The PlantPAx™ objects are now embedded in the firmware. This will allow for a smaller footprint, consistent delivery, and a single place to configure alarms, setpoints, and interlocks, configuring via popup dialogs. The other really nice thing is that when you are trying to figure out what is going on, you no longer have to sift through pages of ladder logic.

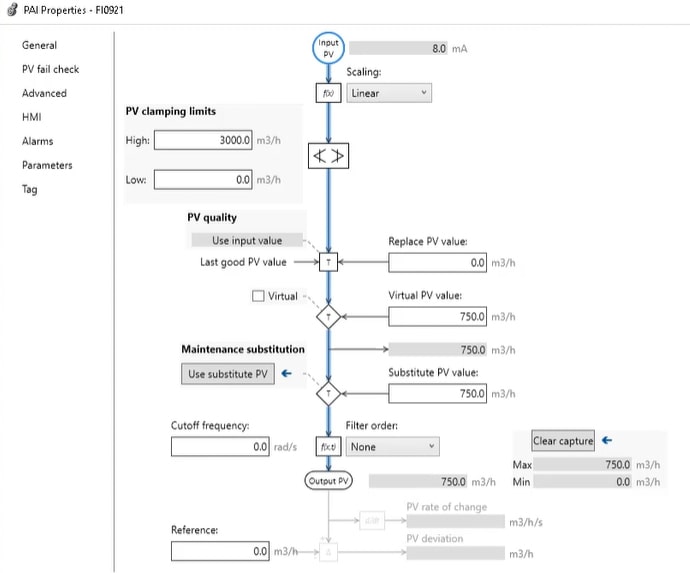

Another exciting feature of the new process controller is that the objects now come with animated Scientific Apparatus Makers Association (SAMA) diagrams. SAMA diagrams show the flow of information with a control system from top to bottom. The sensor is at the top, and the output is at the bottom. In the figure below, the blue line shows the current flow of information.

When a problem happens, these diagrams will allow maintenance to go into the PLC to see where the problem lies.

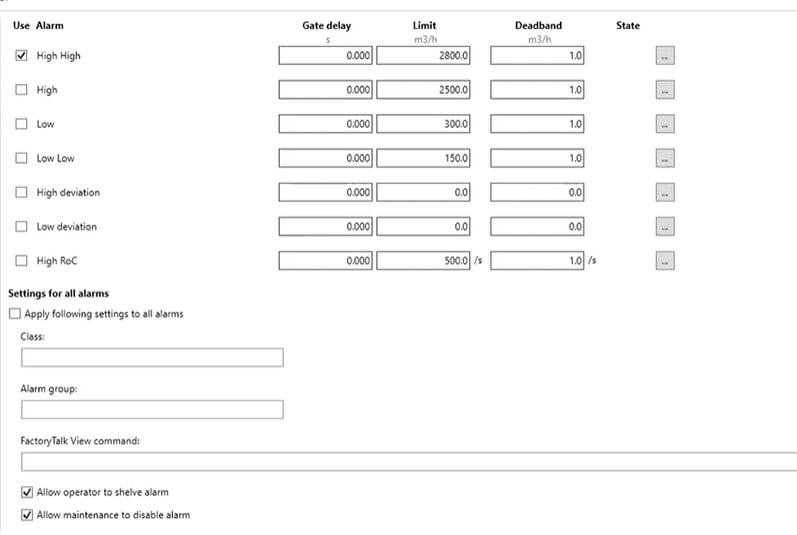

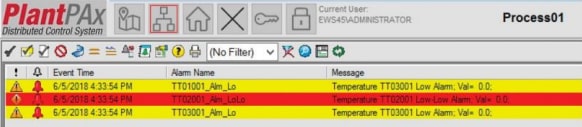

Alarming is also configured in the PLC rather than programmed. Alarms can be created, grouped, and prioritized all from a convenient popup within the process controller. These alarms are then displayed in canned objects for the operator, allowing for built-in navigation to allow quicker operator response time.

Here is an example of how the alarms are configured in the process controller:

This is an example of a canned alarm banner:

Another new feature within the process controller is equipment ownership and arbitration.

This feature is also configurable rather than programmed and allows for equipment queuing with prioritization rules! These equipment queues are also available for the operator right from the human machine interface (HMI)!

So, the next time you’re woken up in the middle of the night because the plant has an issue, remember all the new features of the new process controllers can be leveraged to allow the controls engineer to get more sleep and be more alert during working hours. There are also a lot of productivity gains for the company, but sleep is important to anyone that supports a 24/7 manufacturing facility.

For more information, please refer to these short videos: