Blog > Automation > Reliable DC Power Systems

Reliable DC Power Systems

8/6/19 | Tom Hopkins, Rexel Technical Consultant

Blog > Automation > Reliable DC Power Systems

8/6/19 | Tom Hopkins, Rexel Technical Consultant

In today’s automation world, downtime is not an option—so you need a reliable DC power system. Control devices are more sensitive to power interruptions, and a power issue can cause data loss and long restart times, costing you valuable production time. So, how do you guard against a power interruption to your 24 VDC control devices? What might cause an interruption?

Let’s start with a solution to the failed power supply scenario.

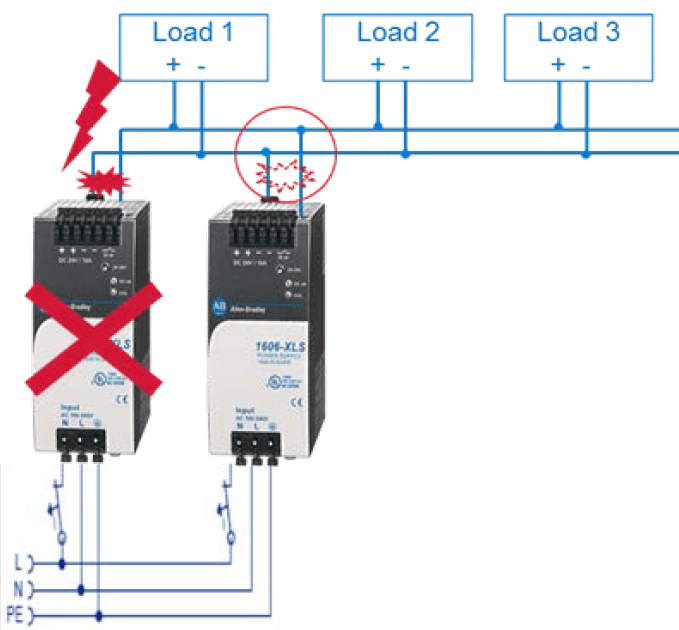

To obtain reliable DC power, the initial thought process might be to place two DC power supplies in parallel. In theory, if one dies, the other will still supply the power needed. But let’s look at this a bit closer. What if you have an internal short circuit in the secondary side of one power supply? The defective unit will become a load for the other power supply, and the output voltage of the good power supply is also shorted.

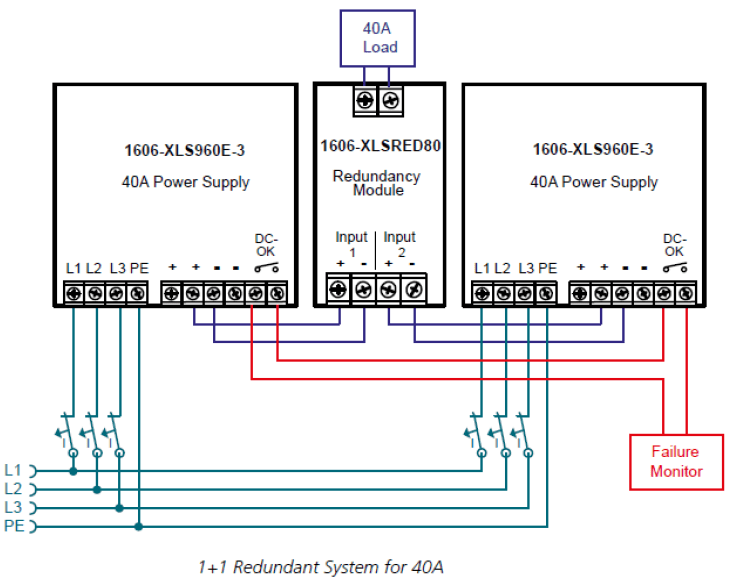

A better way to obtain reliable DC power is to have both power supplies connected in parallel but decoupled from each other. You can accomplish this using a redundancy module. This module uses MOSFET technology stop back feeding. The set up described and shown below is called “1 + 1 redundancy.” When designing this solution, make sure that either power supply can handle the load on its own. And it’s important also to monitor the “DC-OK” contacts, so you can have a failed unit replaced in a timely fashion.

© Rockwell Automation®

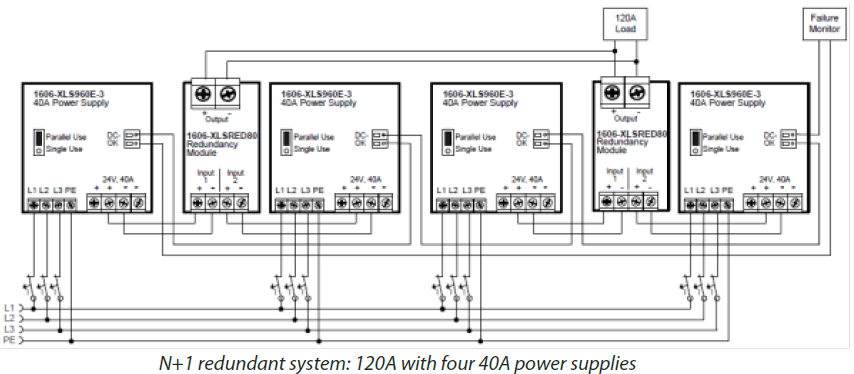

Now suppose you have a larger amperage load but still want redundancy. You might use a combination of four power supplies and two redundancy modules. The set up described, and shown below, is called “N + 1 redundancy.”

© Rockwell Automation

A failure in any one power supply still produces enough amperage to carry the load.

Perhaps you want even more insurance that your control system won’t go down. Then you’ll have to consider the possibility that the AC power might be interrupted. There could be an AC voltage sag or complete interruption.

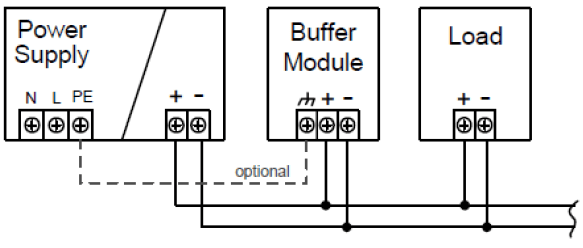

It’s a proven fact that 90% of power quality issues are quick voltage sags of less than 200 milliseconds. These sags are fast enough not to be detected without the right equipment but capable of causing issues. Voltage sags are introduced on the utility line due to uncontrollable events; think about a squirrel grabbing a power line from a tree. That quick fault sends a ripple over the grid that can travel many miles to your production facility. To protect against these common events, you can place what is called a “buffer module” downstream from your 24VDC source. These are capacitor-based modules that will ride through those short duration sags and keep your control system up.

© Rockwell Automation

You could also introduce an AC sag corrector upstream of your 24VDC power source. This device is called a “dynamic sag corrector” (DySC). While it is also an effective capacitor-based solution, it is more expensive and designed to protect a much larger amount of power. I’ll cover this device more in-depth in a future posting.

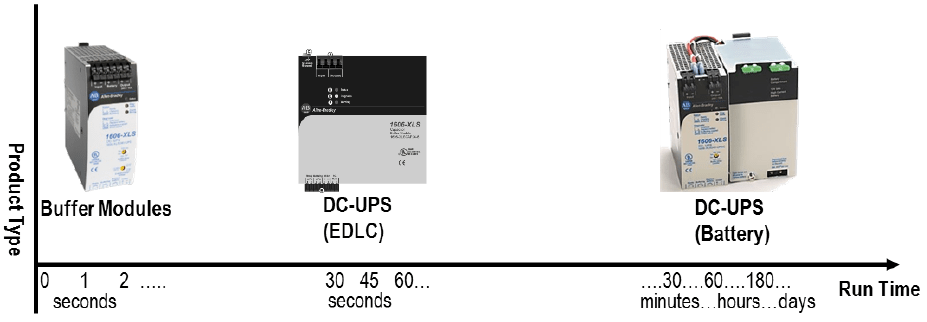

If you are concerned about longer duration outages, there are also two versions of uninterruptable power supply (UPS) you can consider. An electrochemical double layer capacitor (EDLC) will give more uptime than a buffer module, and of course, you could introduce batteries to carry the load. Below is a chart showing the options versus run time.

Depending on your application and risk tolerance, there are many ways to design your control power system. Now you have a start on understanding the options. For more details on available power supply products, you can begin here. Our many qualified account managers and specialists are always available to assist. Contact us today!