Blog > Automation > Top 3 Remanufacturing Benefits

Top 3 Remanufacturing Benefits

5/21/19 | Ryan Beauchemin, Rexel Technical Consultant

Blog > Automation > Top 3 Remanufacturing Benefits

5/21/19 | Ryan Beauchemin, Rexel Technical Consultant

Today, manufacturing facilities are challenged with doing more with less—less staff, less capital, and of course, less time. Expectations are focused on maintaining lower operating budgets while increasing efficiency and optimizing operations. Remanufacturing can help you achieve these goals. Remanufacturing benefits include like-new parts, support for obsolete parts, and lower maintenance budgets.

Remanufacturing is often confused with other repair services. But whereas repairs fix known or obvious issues, remanufacturing returns parts to their original (like new) state. Most repair companies may only find and fix the symptoms instead of the underlying problem. Remanufacturing services include disassembly, thorough cleaning, firmware and hardware upgrades (as necessary), inspection and testing, and a new factory seal and warranty.

The number one benefit of remanufacturing is that it returns equipment to original-equipment-manufacturer (OEM) specified condition, meaning it will function and appear as it did the day you took it out of the box.

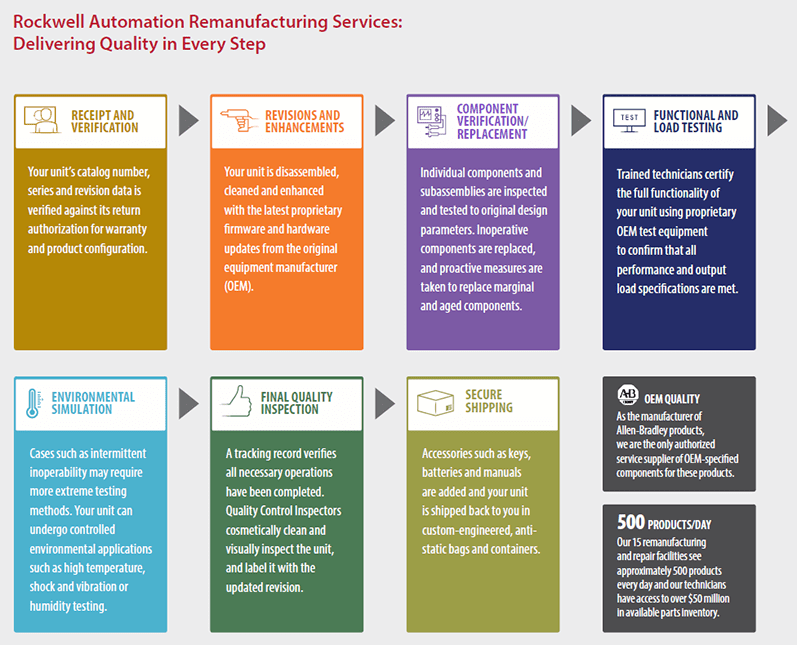

Rockwell Automation® has an excellent example of how these services work. As you can see in the diagram below, they use an ISO-certified comprehensive seven-step remanufacturing process. Starting with receipt and verification, the part is checked for a factory warranty. Once verified, the part is then completely disassembled and thoroughly cleaned with their environmentally friendly cleaning process. Then the part is fitted with the newest firmware and hardware revisions. Using original OEM-specified components, the part is restored to its original condition or better with new marginal components to ensure longevity. Prior to final inspection, they run full-load testing and environmental testing. When the part passes all testing, it’s time for a final inspection, a new factory seal, and a warranty that matches or beats the original factory warranty.

© Rockwell Automation

In a perfect world, a maintenance manager would be able to regularly upgrade all their production lines with the most modern equipment before it becomes obsolete. Obviously, this does not happen very often. Today, many factories are challenged to continue maintaining the currently installed equipment for decades. Remanufacturing services can be used to make sure obsolete parts continue to function as if they were new. Rockwell Automation can fully support its own Allen-Bradley® and Reliance® components well into obsolescence with the same factory-specified OEM components that were used when the product was manufactured. Remanufacturing services like this can keep aging components as reliable as they were when they were first installed.

Maintenance managers are challenged to lower their maintenance budgets while raising the overall equipment effectiveness (OEE)—talk about balancing acts! Sometimes this can seem like an uphill battle, but quality remanufacturing can level the field. Manufacturing companies have been experiencing success by monitoring two key factors: mean time between failures and mean time to repair. Remanufacturing services are designed to increase your mean time between failure rates by restoring parts to new condition (rather than repairing something broken). This will lower your downtime events exponentially as each part gets remanufactured. And suppliers like Rockwell Automation offer turnarounds as low as 24 hours, with an exchange option in one of its service levels. By monitoring mean time between failures and mean time to repair alone, maintenance managers have been able to Increase their OEE all while lowering their monthly maintenance costs over time.

Did you know that out of all the repair facilities in the world, Rockwell Automation is the only full remanufacture provider for your Allen-Bradley and Reliance equipment? The proprietary remanufacturing process can help improve your overall equipment effectiveness, stabilize your maintenance budget, and reduced your unplanned downtime. And as an Authorized Rockwell Automation Distributor, we can help you get that new-part smell. Contact us today!