Blog > Automation > 4 Signal Conditioner Benefits

4 Signal Conditioner Benefits

7/2/19 | Scott DeVost, Rexel Technical Consultant

Blog > Automation > 4 Signal Conditioner Benefits

7/2/19 | Scott DeVost, Rexel Technical Consultant

In simplest terms, signal conditioners manipulate analog signals to meet the requirements for further processing. In industrial environments, they isolate, transmit, convert, split, and amplify to improve process reliability. They also provide isolation via galvanic isolation, save panel space, standardize on a signal type, solve mismatched signal issues, reduce wiring with loop-powered units, and improve troubleshooting.

Let’s look at a few of the top benefits of using signal conditioners.

Signal Conditioners receive the signal from the field device, isolate the signal, and then reproduce and transmit the higher quality signal to the PLC. Signal conditioners can isolate the PLC from the transients and noise that can occur in the environment, as well as eliminate potential differences from long cable runs and common reference points.

There are three different types of isolation available:

All isolation types eliminate potential differences caused by long wire lengths and common reference points.

One of the most common uses for signal conditioners is to convert one type of signal into another. For example, if you have a sensor that has a 0…10V output and your PLC needs a 4…20mA, the signal conditioner can convert that signal to the PLC.

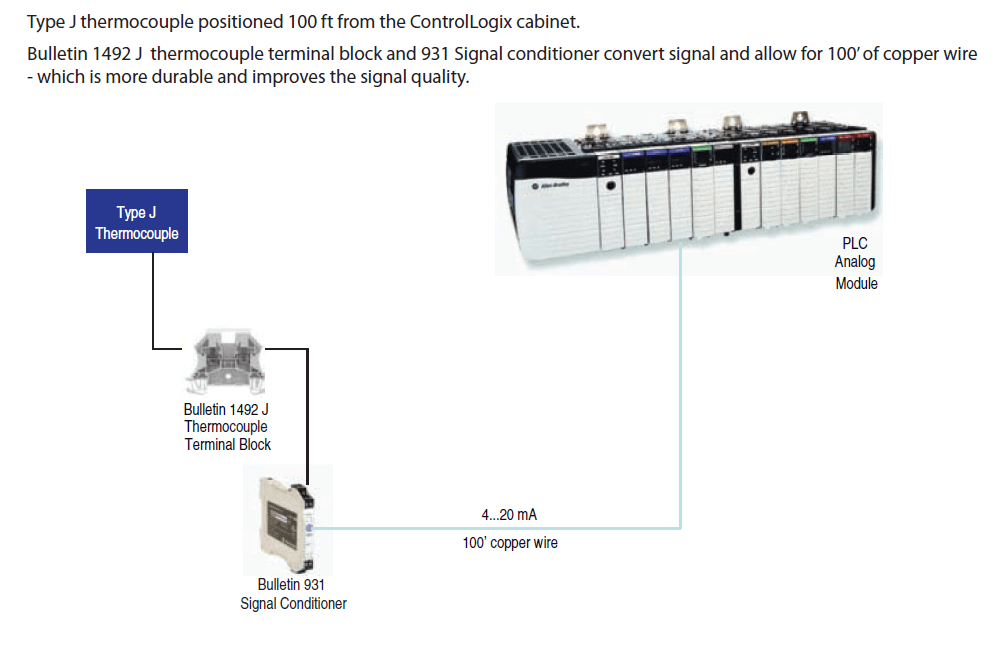

Another example of a common conversion is thermocouple to an analog signal. Thermocouple wire is expensive, and the PLC will need a thermocouple input card. By converting the signal to a 4…20mA you will only need a short distance of thermocouple wire, and the rest of the run can be standard copper wire. The PLC input can now be the standard analog input.

Signal conditioners can be used to split one input signal into two output signals. This application can be useful when you want to have multiple signals for control and visualization.

Signal conditioners can amplify signals from low-level to high-level analog signals. The thermocouple scenario mentioned above is an example. It has a millivolt output and can be converted to a higher-level standard analog signal.

The newest addition to the Rockwell Automation® signal conditioner line is the 931N (Nano Series). The Nano series is only 6.1mm wide and has a DIN rail power option. So if you have multiple units, you won’t need to wire each unit separately. The Nano series also has units available that are loop powered, so they won’t need a separate power supply. The 931N also carries extensive certifications and approvals from UL, CSA, CE, ATEX, IECEx, FM, DNV-GL, KC, RCM, Hazardous Area (Class1 Div 2/ Zone2).

We can help you find the right signal conditioner to meet your needs. Our Automation Specialists are the experts—keeping up to date on all the latest technology and trends. Contact us today!