Blog > Electrical > Mitigating Voltage Sag

Mitigating Voltage Sag

4/5/22 | Kevin Beach, Rexel Technical Consultant

Blog > Electrical > Mitigating Voltage Sag

4/5/22 | Kevin Beach, Rexel Technical Consultant

I certainly don’t want to make light of the plight of a squirrel or other such critter when it gets zapped, but this is one of the causes of voltage sag. A voltage sag is defined by IEEE as when the RMS voltage drops over 10% of nominal voltage for a half cycle to one minute. If the sag lasts longer than 60 seconds, it is called a sustained interruption.

Let’s start off by comparing power quality with power reliability. Reliability is the measurement of the continuous supply of electricity and is determined by the number and duration of outages. An outage is a drop to zero voltage. These events are tracked by the utilities and typically could be 99.999% reliable. It’s that other .001% that gets ya!!

Power quality is about fluctuations in electricity as it reaches your facility (really the only place that matters to you, right?). These fluctuations could be momentary interruptions, harmonic distortion, voltage sags or swells, and other electrical distortions. These events are not tracked by the utilities. In fact, utility companies are only responsible for the power reliability, and the quality of your power is, by and large, your responsibility.

Quality events are found on both the utility side and your facility side. On the utility side, it could be weather-related, construction, our friend Squiggy the Squirrel, and other events.

In your facility, it could be the starting of large loads (motors), arc welders, poor connections, and other random causes.

Whatever the cause, the impact on your plant can be huge. It can cause immediate process shutdown, loss of delicate instrumentation and tooling, scrapped product, and major downtime. And your lights may not even flicker!!

In this discussion, we are dealing with voltage sags up to five seconds, which represents virtually all the sags you will see. While it would seem that having a 15% sag on one phase of your line for three cycles isn’t significant, that is not necessarily the case. For most of us, we probably wouldn’t be seriously impacted, but in many industries, this relatively minor power disturbance could be devastating. In some industries, it could cause the breakage of extremely expensive tools, and in other situations it could result in the process stopping, incurring millions of dollars in downtime. Obviously, this is not acceptable in these cases.

When a sag occurs, a re-closer switch on the transformer attempts to correct the situation, and if it cannot within two seconds, trucks are dispatched.

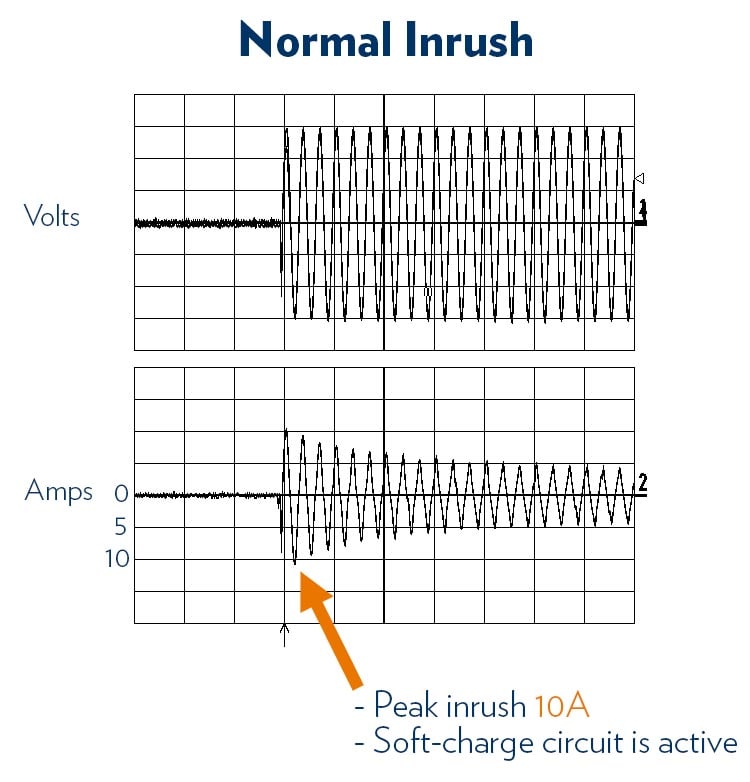

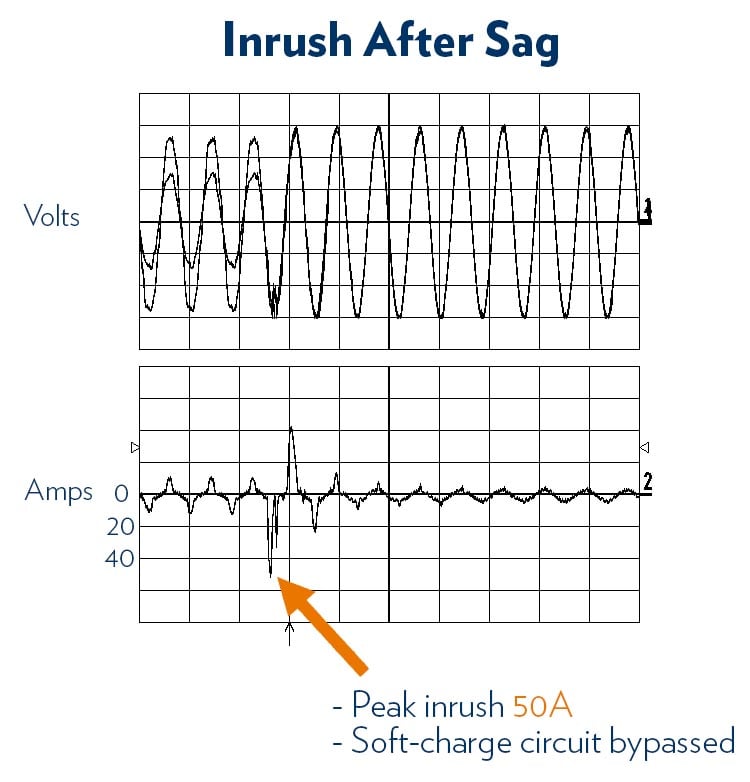

Events downstream of this switch are outages and upstream are voltage sags. If your plant is downstream and the re-closer switch is successful, you could also experience a voltage sag. In both sag cases, when the voltage returns, you can experience a spike in the voltage.

Note the change in the scale to make these fit in the same space!!

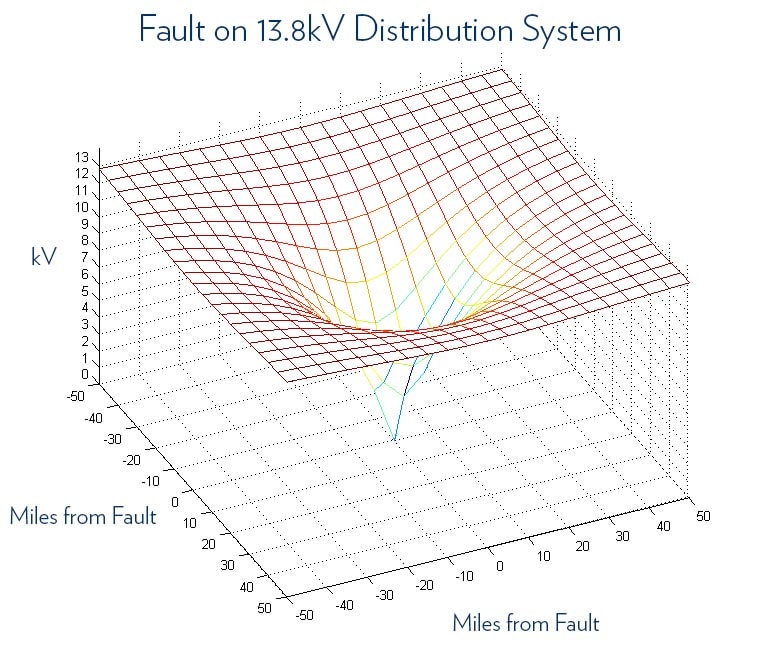

The depth of your sag depends upon your distance from the event.

There are a number of ways to do this, ride through to generator, online UPS, flywheel, or DySC® from Rockwell Automation®.

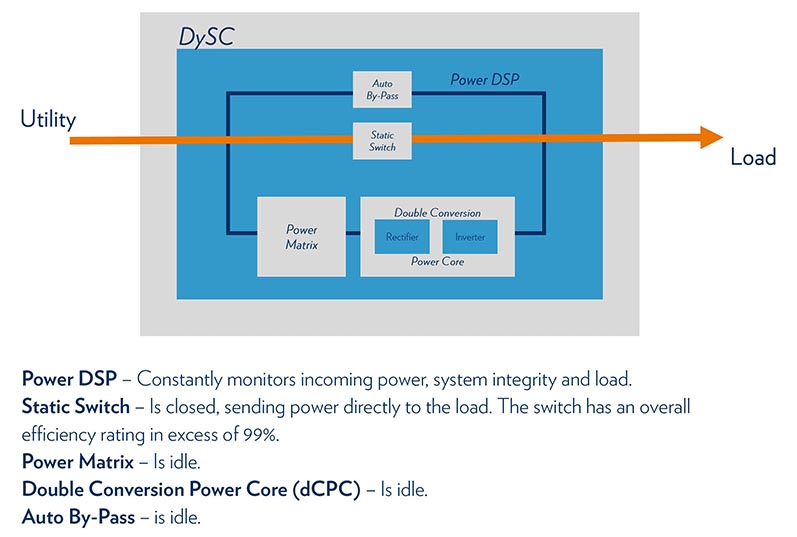

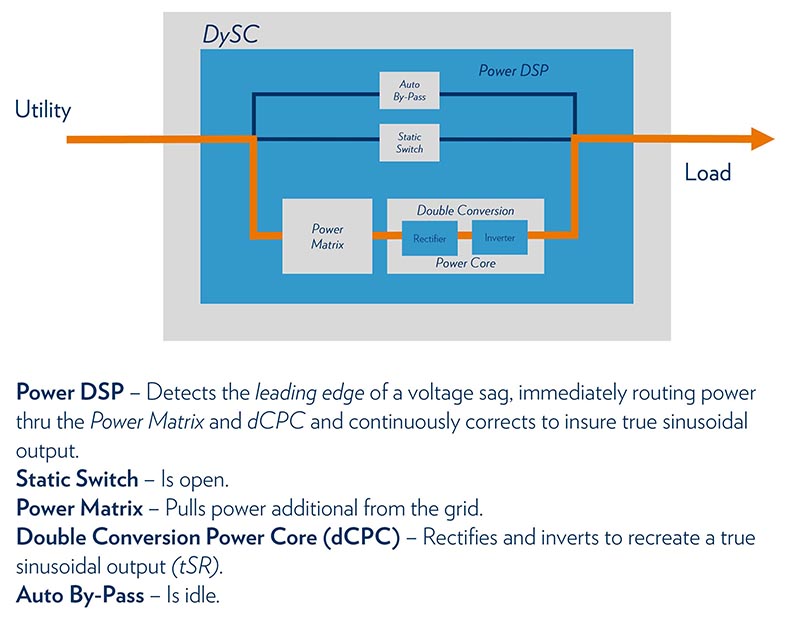

DySC (pronounced “disk”) is an adaptive power supply that optimizes the remaining power during a voltage sag by using patented inverter technology to compensate for the sag. This provides uninterrupted optimal power flow to the load maximizing uptime, minimizing inventory loss, and reducing equipment breakage and maintenance. DySC can provide up to five seconds of ride through.

It is available in single and three-phase versions up to 2400 amps!

DySC utilizes capacitors for power storage, not batteries, providing an extremely reliable solution. We all know batteries are fairly short-life devices, but capacitors last for many years (we are familiar with the durability of capacitors in variable frequency drives). In normal operation, DySC monitors power quality continuously, while the power electronics are in standby mode 99.999% of the time. This makes DySC the most energy-efficient power quality device available.

When a sag occurs, DySC is “ON” in under two milliseconds.

A medical facility experiences multiple deep voltage sags of less than half a second every year. This works out to DySC power electronics actually being “ON” less than 30 seconds per year. The use of capacitors rather than batteries dramatically increases the reliability of the device. There are DySC systems that have been in place and working for over ten years with virtually no maintenance ever being performed. No other sag mitigation device even comes close to this!!

Any industry with high downtime costs or critical processes should look at DySC as a solution to sag events.