Blog > Automation > Avoid Ground Loops with Signal Conditioners

Avoid Ground Loops with Signal Conditioners

12/11/19 | Tom Hopkins, Rexel Technical Consultant

What is a Ground Loop, and Why Should I Care?

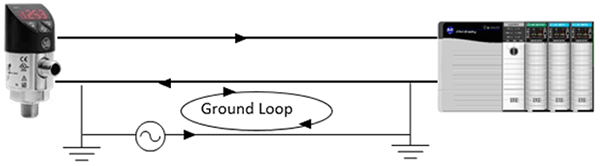

Erroneous input data in your industrial process can cause problems. Ground loop noise can adversely impact process data (temperature, pressure, flow, etc.). Because this data can be critical to an industrial process, it’s important to understand the possibility of this noise, what causes it, and how to remediate the issue.

GROUND LOOP EFFECT EXPLANATION

If two devices are connected, yet grounded in different locations, there can be a difference in potential between those two grounds. As you may know, a difference in potential in a circuit is going to induce a flow of electrons. This will create a loop current that is known as a “ground loop.” Since the induced current runs along the same wires as the analog signal, the noise of the ground loop will often cause erroneous signal data.

The Solution is a “Signal Conditioner”

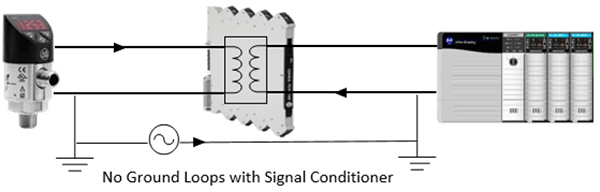

If you put a break in the ground loop circuit, the induced current will stop, and your signal will be undisturbed. Breaking the circuit is called “isolation.” But how will your signal get through if you break the electrical connection? This is done by adding a specialized device that is called a signal conditioner or an optical isolator. The signal conditioner still allows the passing of your signal without an electrical connection.

© Rockwell Automation

How a Signal Conditioner Works

A signal conditioner works by taking the input signal and converting it into optical signals with an LED. That LED then sends light to a photodiode that converts the signal back to electrical. You can see why another name for this device is an “optical isolator.” Through the simple brilliance of this device, the signal can pass through without an electrical connection, and the ground loop problem is averted.

What Else Can I do With a Signal Conditioner?

Using the same isolation technology enables you to do other helpful things.

- Protect devices from transients. Electrical surges can be stopped by the optical isolation in the device. A signal conditioner has an interrupt rating of 2.5 kV and will stop many surges from damaging your equipment.

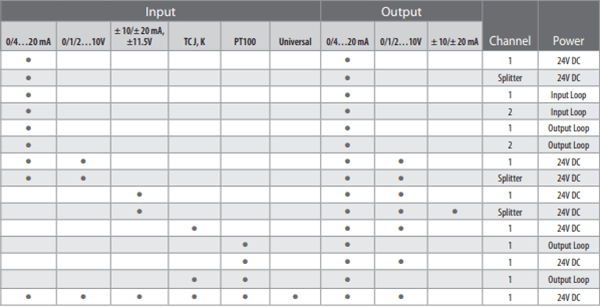

- Amplify signals. There are signal conditioners that will take a low-level signal and turn it into a larger signal.

- Split a signal. There are signal conditioners that will split a signal into two channels if you need a signal to go to two devices

- Convert signals. As an example, you might have a sensor that sends out a 0-10 volt signal, but your processor can only read a 4-20 mA signal. There are devices to convert between MANY types of signals, including thermocouples.

Ready to Avoid Ground Loops?

Now that you understand signal conditioners, you may be thinking: “This is great stuff! Where do I find these magic devices to help me with my industrial process?” Rockwell Automation has a comprehensive line up of signal conditioners. You can learn more here. And if you have questions or are ready to get started with this technology, contact us today.