Blog > Automation > Inertia Ratio: Avoiding an Inertia Mismatch

Inertia Ratio: Avoiding an Inertia Mismatch

5/9/19 | Chris Williams, Rexel Technical Consultant

Blog > Automation > Inertia Ratio: Avoiding an Inertia Mismatch

5/9/19 | Chris Williams, Rexel Technical Consultant

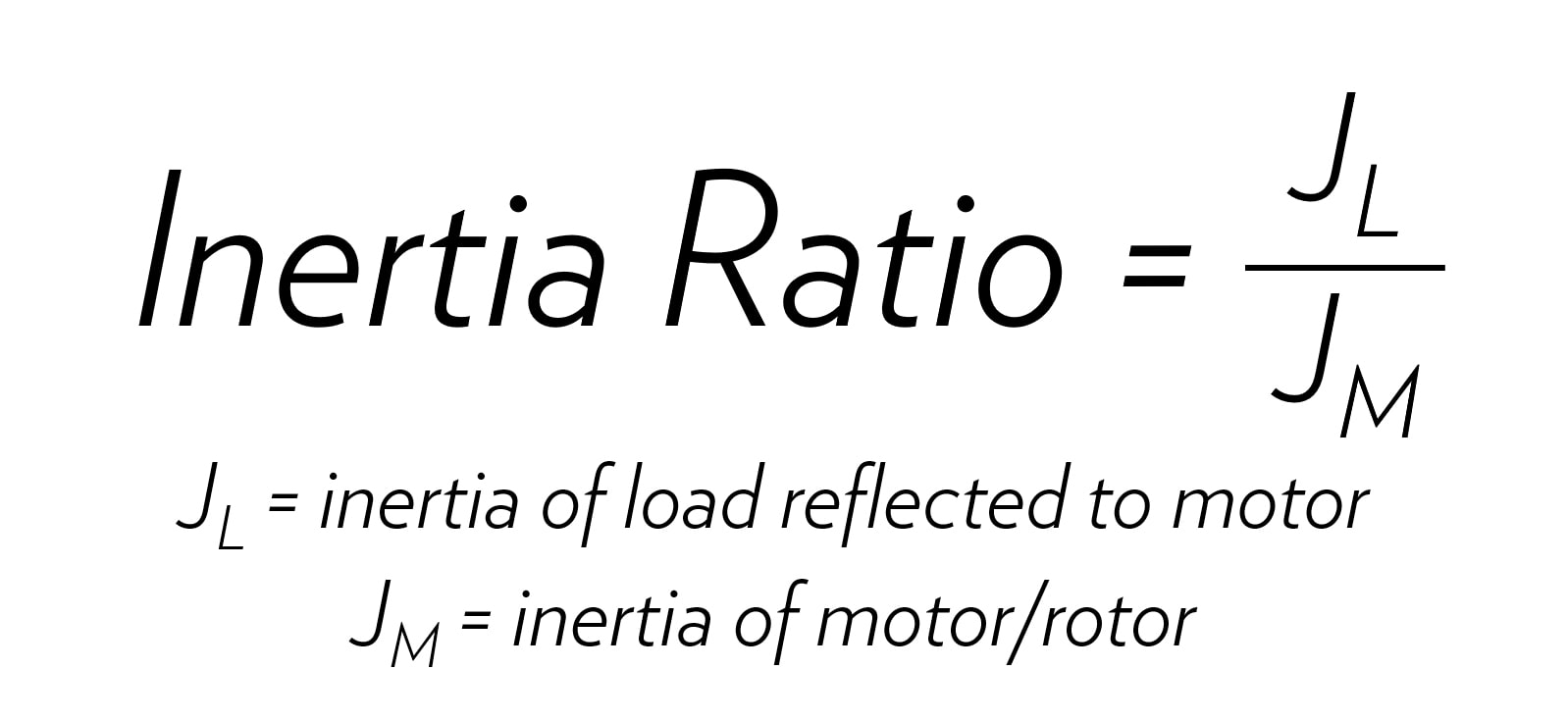

Inertia is an object’s resistance to a change in speed. The heavier or dimensionally larger an object is, the higher its inertia will be. In a motion control or servo system, both the motor and load have inertia. The ratio between their inertias will affect the performance of the system. This ratio is one of the most important aspects of servo motor sizing and one of the most overlooked.

Click Here to Download our Free Motion Control Fundamentals Guide

Motor inertia is a specification published by the motor’s manufacturer and is driven primarily by the size of the motor’s rotor. The load inertia is calculated by adding together the inertia of all the moving parts (belts, screws, rack and pinion, the external load, and the coupling).

For the servo system to control the load effectively and efficiently during acceleration and deceleration, the motor and load inertias should be as close to equal as possible, but a 1:1 inertia match is rarely practical or achievable. Many factors affect what would be considered an acceptable inertia ratio, but one of the most important is the system compliance or wind-up. Mechanical components are not perfectly rigid, and as more compliant components are added, the more compliance the system will have. System compliance is largely driven by more flexible components such as belts and couplings. In general, the higher the compliance, the lower the inertia ratio should be.

There’s no formula for determining the ideal inertia ratio, but most servo sizing guidelines aim for the inertia ratio 10:1 or lower. Higher ratios cause the motor to work harder than necessary and can lead to increased settling time during aggressive moves, which decreases efficiency and increases operating costs and cycle times. With a proper inertia ratio, the tuningless features in Kinetix® servo drives can be used to eliminate any need for an engineer to tune the system, resulting in low maintenance and quicker startups. If the inertia ratio is very high (over 10:1), then the motor may not be able to control the system at all, even at a standstill. This will lead to the motor using an excessive amount of power just to keep the load stationary or will require a lot of engineering time to tune the system into a stable state.

If the inertia ratio is too high, there are two ways to reduce it: increase the drive ratio (output distance per motor rev) or use a larger motor. Gearboxes are frequently required in belt-driven systems because of the low mechanical advantage of the pulleys. They can also significantly reduce the inertia ratio of the system since the gear ratio has an inverse square effect on the inertia of the load.

The second method for reducing the inertia ratio is to use a larger motor with higher inertia (sometimes moving to a medium inertia motor). However, because of the space and cost required, a gearbox is the preferred solution.

We can help you control motion safely, prolonging the life of your machines. Our Motion Control Specialist offer expert advice and recommend comprehensive solutions. Contact us today!