Blog > Automation > Safe Stopping Options Explained

Safe Stopping Options Explained

2/19/19 | Chris Williams, Rexel Technical Consultant

Blog > Automation > Safe Stopping Options Explained

2/19/19 | Chris Williams, Rexel Technical Consultant

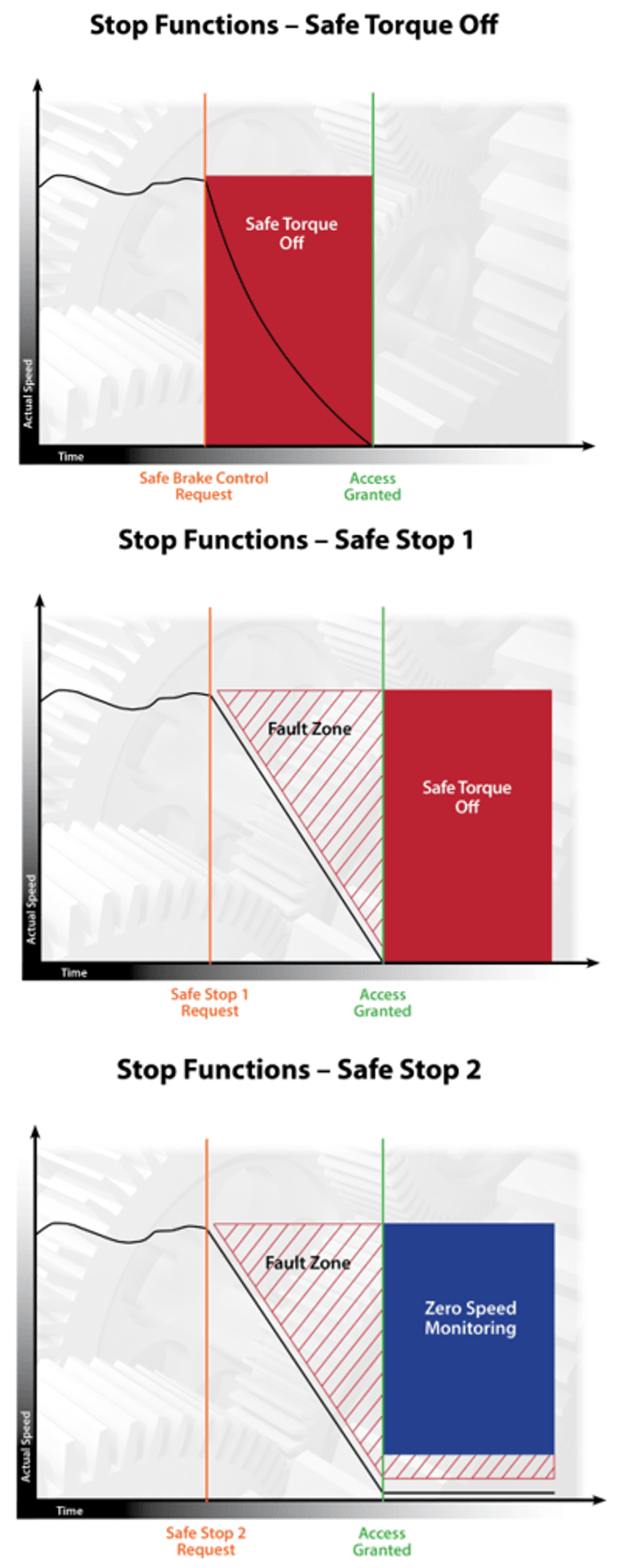

The Safe Torque Off (STO) function is used to prevent unexpected motor rotation in the event of an emergency while the drive remains connected to the power supply. This is a very common, industry-standard way of keeping an operator safe while around moving equipment. While STO is great for ensuring a motor doesn’t become energized, it can cause issues when having to stop a loaded machine. To bring high inertia loads to a more controlled stop, we can use a newer function called a safe stop.

To safely bring a load to a stop, we have two options: safe stop 1 (SS1) and safe stop 2 (SS2). Both work in the same manner to bring the load to a stop but differ once the motor is at a standstill.

Using SS1 reduces the risk of danger and increases the productivity of a system by bringing the load to a controlled stop using the active torque of the motor. This allows for reduced safety clearances in a machine, potentially reducing the overall footprint of a machine or system. Using SS1 also eliminates the need for wear-prone mechanical brakes for stopping the motor. Once the motor is verified to be at a standstill, the drive enters an STO state.

SS2 operates like SS1 in how it brings the load to a rapid, controlled stop, but once the motor is verified to be at a standstill, the zero-speed condition is monitored through the safety controller while the motor torque is used to hold the load in place. If the load begins to move for any reason, the drive will immediately enter STO and cut power to the motor. Using SS2 can eliminate the need to rehome a machine after entering the safe stop because the motor remains energized and does not lose its position. Rotating blade mechanisms are another example where SS2 is helpful. If an operator accessing a machine needs to put it into an STO state to work on it safely, without the addition of interlocks, the rotating blades may be able to move and cause harm. With SS2, the motor will keep the blades stationary, reducing the risk of operator injury.

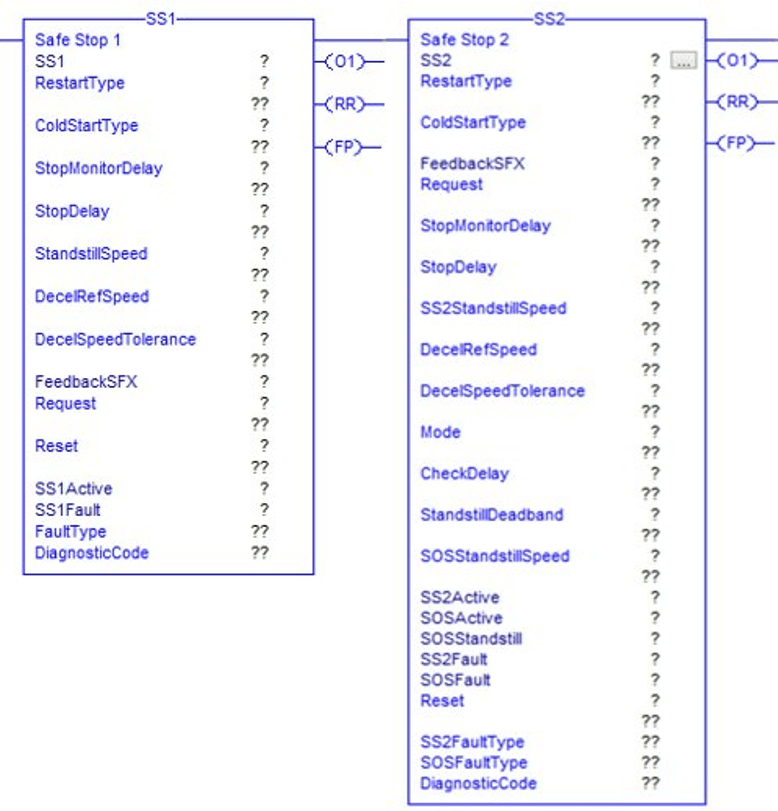

Both SS1 and SS2 work with the flexibility of networked safety functions. Because they are run through a safety PLC, all the parameters can be adjusted on the fly based on machine conditions and user inputs, if necessary. Compared to other safety functions, the deceleration rate of both commands is adjustable and can be programmed to protect both personnel and equipment more efficiently.

The most significant difference between the two stops is that only SS1 can be used in emergency stopping situations. Another difference between these two types of stops has to do with the end state. In an SS1 function, the motor enters STO once it is verified to be at a standstill. In SS2, the motor remains energized and enters zero-speed monitoring or a safe operating stop.

The differences between the way these two functions operate should make it clear that SS2 is not acceptable for emergency stopping situations. If an operator is in the way of moving tooling and SS2 is commanded by the e-stop, they may be trapped by the equipment or in further danger because the motor remains energized and can still output torque at the end of the stop.

Rockwell Automation® has integrated these new functions into the advanced safety version of the Kinetix® 5700 servo drives and when used with the new 5580 GuardLogix® controllers can help increase safety and production plantwide.

Our Automation Specialists have the answers to all your motion control questions. From increasing safety to maintaining productivity, our specialists will assess your situation and recommend solutions to meet your needs. Contact us today!