Blog > Automation > VFD Series Part 6: Is Safe Torque Off for Me?

VFD Series Part 6: Is Safe Torque Off for Me?

2/14/19 | Kevin Beach, Rexel Technical Consultant

Blog > Automation > VFD Series Part 6: Is Safe Torque Off for Me?

2/14/19 | Kevin Beach, Rexel Technical Consultant

In today’s safety-conscious manufacturing environment, this is a very reasonable question to ask. With all the new safety-rated switches, PLCs, and other devices, is safe torque off (STO) something you could really use, and is it worth the investment?

Right off, I’ll say, given the minimal cost involved with drive safe torque off, the investment is truly a no-brainer even if you don’t use it at first. STO is designed to remove power from the gate firing circuits of the drive output power devices (IGBTs). With the power removed, the drive output power devices cannot turn on to generate AC power to the motor. When used in combination with other safety devices, it can satisfy the requirements of IEC 61508, IEC 61800-5-2 SIL 3, ISO 13849-1 PLe, and Category 3 for safe torque off (STO). The safety rating also depends upon the drive selected, so be certain to work with your Specialist. One really nice side benefit is the drive control remains powered, so you don’t lose communications resulting in further loss of valuable production time.

So, let’s get started. If this is a new, new-to-you, or extensively rebuilt piece of equipment, then you should absolutely start with a risk assessment. This would be done by a team of people who all have a need to touch the machine at various times and should include the operators, engineers, maintenance people, and anyone responsible for cleaning the machine. There are many ways to evaluate the risk but a common one is called the hazard rating number (HRN) system where numerical values are assigned to likelihood of occurrence (LO), frequency of exposure (FE), degree of possible harm (DPH), and number of persons affected by a situation (NP). NP is why it is so important to represent everybody. These values are used in the following calculation:

The values for each of these varies tremendously. For example, LO goes from .033 for almost impossible to 15 for certain, no doubt of it happening, so obviously designing the risks out has a huge influence on the HRN. And given the final score needs to be less than 10, minimizing contact with the machine and designing the risk out is a pretty good way to get started.

And a little something to keep in mind, when it comes to safety standards in the US, there is no such thing as being grandfathered. When a standard is deactivated and replaced, the new standard is the law.

So, when does STO come into play? First, let’s be certain when STO is not an option. If there is a need for electrical or mechanical repair or machine component replacement, you must go through the normal LOTO (lockout/tagout) process to ensure all energy is dissipated in the system, including electrical, pneumatic, hydraulic, and inertial—any stored energy that could be released causing unexpected movement and injuries.

STO is designed for use during routine machine operation for things like clearing jams and the like. So, how does it work? Quite simply, STO inhibits the output of a VFD and does not allow the drive to generate sufficient current to create torque. When the motor has stopped, it cannot be started again until the STO function is removed. Depending on the drive, the device could meet PLe SIL3 safety.

The picture to the right is a good example of where STO should be considered; one hand in the machine and another on the start button, not to mention the lack of safety glasses.

From the perspective of safety, two stop categories must be considered. Stop Category 0 is achieved with immediate removal of power resulting in coast to stop. In some situations, this is acceptable, but, when it is not, you should use Stop Category 1, which leaves power on the drive for enough time to achieve a controlled stop. In either stop category, no further motion can happen so long as the STO function is in place. There is a Stop Category 2, but that is considered a production stop.

When used in conjunction with approved safety rated switches or PLCs and Interlocking and/or Guard Locking guard switches, an acceptably safe environment is created for the machine operator to enter the machine for routine work.

There is, of course, a little twist in this, and it is called safe speed monitor (SSM). This option is used when the process requires some motion in the machine, such as threading a paper machine. One application I was personally involved with was on a textile machine. Periodically, the operator needed to go in the machine with gloves and a Teflon pad to clean the chrome rolls. Obviously, this couldn’t be done at operating speeds, so the SSM would allow the Guard Locking Switches to be opened by the operator when the safe speed was reached. The SSM should always have a thorough understanding of the machine function and be dictated by the results of the risk assessment performed on the machine.

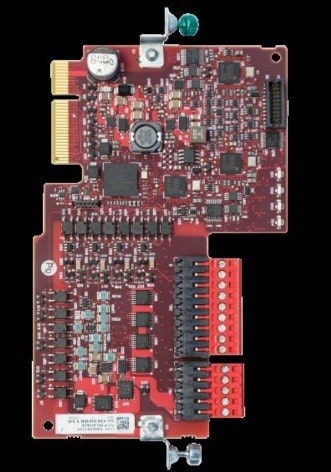

Traditionally, all safety-related components were hard-wired to the controller creating several pain points, such as lots of wire and “where the hell is the short?” Today, safety can be accomplished over Ethernet and STO or SSM is no exception, just be certain the device is designed for CIP Safety. In the case of Rockwell Automation® PowerFlex® 750 class drives, STO would be 20-750-S for hardwired, 20-750-S1 for hardwired SSM, and 20-750-S3 for STO using Ethernet. While the 20-750-S3 can also be hardwired, it is important to remember the 20-750-S is hardwired only with no Ethernet. Rockwell Automation also offers an “all-in-one” 20-750-S4 card for the PowerFlex 755 and PowerFlex 755T drives which incorporates safe torque and safe speed either hardwired or over Ethernet.

So, to answer the question this blog started with, “Is safe torque off for me?”, look closely at your process. Does it require the operator to enter the working area for routine and normal operations? If the answer is yes, then safe torque off is something you should be seriously reviewing. And if you need help making that determination, contact us today.

This is part six of our popular, on-going VFD series. Don’t miss the rest of the series: