Not only does June mark the halfway point of the year, but it is also National Safety Month. It's a great opportunity to bring a higher level of safety awareness to your employees, customers, and community. The safety culture here in the United States has come a long way in the past few decades. "Safety First" has become quite a popular phrase for many employers across the country. However, there's a lot more to be done to ensure people are working safely both on the job and at home. Understanding the hierarchy of controls is a great place to start.

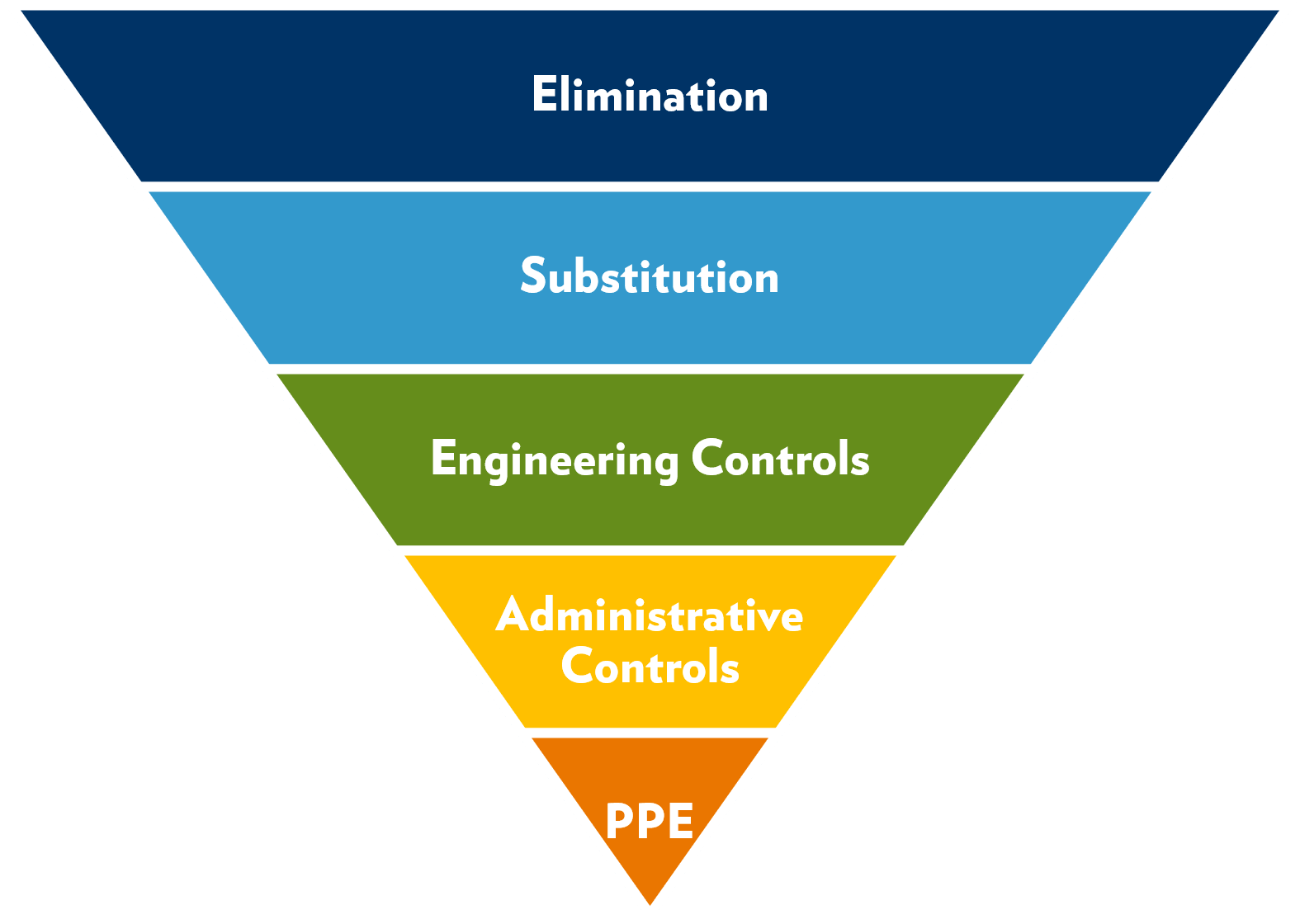

Before doing any job, it's imperative to assess the hazards you and your team could be exposed to and then take steps to mitigate the risk of injury. Once a hazard is identified, five types of controls should be explored. In order, the hierarchy of controls is elimination, substitution, engineering, administrative, and personal protective equipment (PPE).

Here are a few key points to consider as you and your company look to up your safety game on and off the job:

Can you still perform the work without exposing yourself to the hazard? This is the first level of the hierarchy of controls to explore because it offers the best results at no cost. Unfortunately, there aren't many situations where hazards can be eliminated from the work environment. Regardless, the question should still be asked: "Can I still do my job if I were to eliminate the hazardous component of the work?" If the answer is "no," then we move on to the next safety control.

The next level of the hierarchy of controls is substitution, meaning replacing something with a safer option that will help mitigate the risk of injury. For example, swapping corded power tools for battery-operated tools will reduce the risk of slips, trips, and falls because there wouldn’t be any electrical cords to navigate through. While substitution controls are highly effective when it comes to increasing safety, sometimes other risks are introduced to the business, such as poor performance, lower quality, and less throughput. So, while the Safety Manager looks like a hero, the Production Manager or Operations Supervisor takes on additional headwinds in their role.

As the pyramid of the hierarchy of controls narrows, we arrive at engineering controls, adding or revising equipment to make a job or work environment safer. All too often, we see capital equipment running, making the company money, but posing safety risks for the people operating it. Exposed belt drives, turning gears and sprockets, chemicals dripping, and sparks flying. You name it, and we have seen it—from arc flash to unguarded motion, they all increase the risk of injury if not addressed.

When I think about engineering controls, machine guarding comes to mind. Cages, Plexiglass, and metal enclosures are great examples of physical guarding that can be added to machines. If that’s not an option, then electronic light curtains may be the right solution. Either way, machine guarding is a great way to prevent an injury from occurring. Also, inspecting and testing your e-stops is a critical safety measure. E-stops are something we hope we never have to use, but if we need to, we must have the assurance that they are functioning correctly.

Next on the hierarchy of controls is administrative controls, aligning policies and training to ensure your people stay safe. For example, a newly written policy on heavy lifting: Anything over 50 lb. requires a second person or apparatus to lift and transport. It can also refer to a company's disciplinary actions for those who don't follow a safety policy set forth (e.g., written warnings, formal write-ups, or terminations).

The final level of the hierarchy of controls is personal protective equipment (PPE)—the last resort to mitigating the risk of injury. While there are many great products to explore in the PPE world, a great deal of time should be spent exploring the other controls before resorting to PPE. PPE carries the highest level of cost long term, and it offers the least amount of assurance that your people are out of harm’s way. It brings new levels of complexity to day-to-day operations in the workplace. Where there is PPE, policies need to be written and training needs to be conducted on an ongoing basis. Companies that are “PPE-heavy” constantly struggle with their operation costs, carrying costs, and inventory control. Also, production can become directly affected by the PPE you carry in-house. The machine may be working, and the people may be showing up to operate them, but if you don’t have the PPE available to use, you now find yourself in a shutdown situation, which is extremely costly.

We know the thought processes you need to take to mitigate risk and keep your workers safe. No matter where your solution falls on the hierarchy of controls, we can help you with your safety needs. Contact us today!