Blog > Automation > Is it a VFD or Servo Application?

Is it a VFD or Servo Application?

3/2/21 | Andy Lussier, Rexel Technical Consultant

Blog > Automation > Is it a VFD or Servo Application?

3/2/21 | Andy Lussier, Rexel Technical Consultant

Let me start by saying that this is, or can be, a gray area: no ONE solution is absolutely right or wrong. A deeper understanding of the application typically dictates the technology direction (VFD or servo). This discussion outlines some of the technology differences between the two solutions as you consider these technologies for different applications.

We have to start with “What is motion control?”. The definition can be summed up in its simplest form in only four words:

But it is a bit more than that… motion control is the process of managing or directing the movement of machinery or equipment (load) based on a desired machine cycle profile.

It comes in two flavors:

When solving a drive or motion application, you are really considering two concerns based on your application requirements:

There are a few things take into consideration when starting down the path of which solution is best, VFD or servo. First, is your application profile. Are we just running along at a set speed based on a production variable or are we positioning based on a registration input?

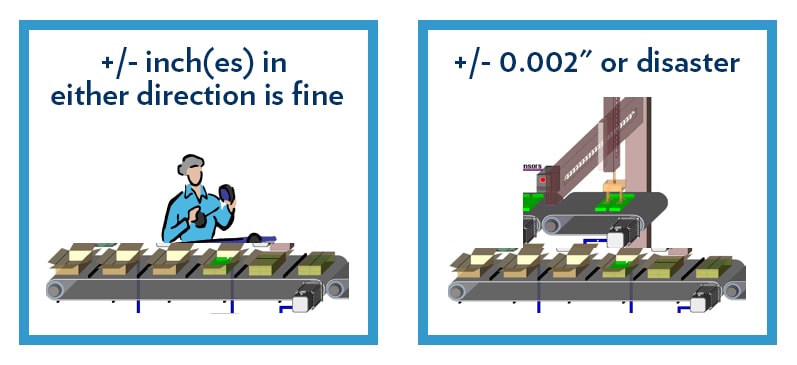

How close do you need to be to your target?

In either case (VFD or servo), you need to size your motor based on the load it is moving and the profile it is running. Moving 200lbs in 30 seconds has a much different requirement than moving 200lbs in 3 seconds. There are several tools available for sizing your application and determining your motor requirements. (Learn more by reading How to Size a Servo Axis.)

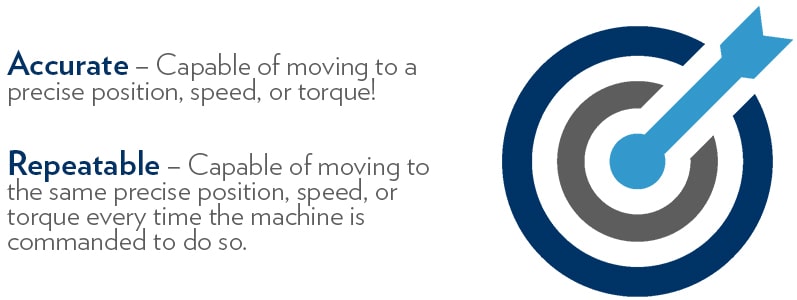

Automated equipment employing “Closed Loop” Motion Control will provide machine movement that is:

Depending on the finer requirements of your application, you may be able to achieve the desired control with either a VFD or servo solution. Inherently, a servo system is a closed loop system where we are always trying to close the error between what the motor is commanded and what the motor is actually doing (position, speed, torque). Some VFDs have this capability, but there are additional hardware requirements in order to do so, mainly a feedback device (encoder).

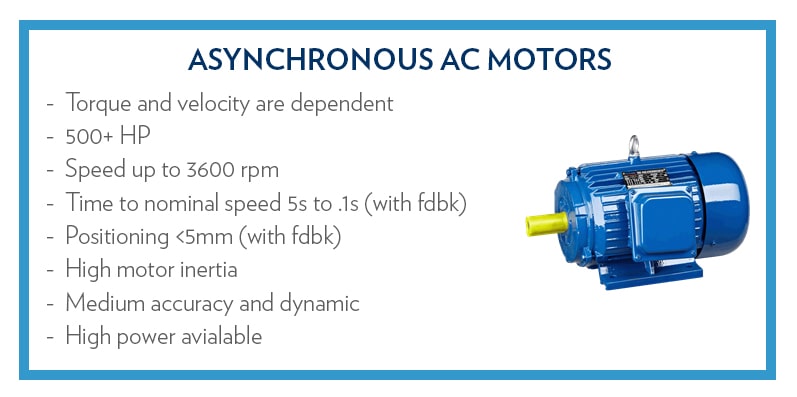

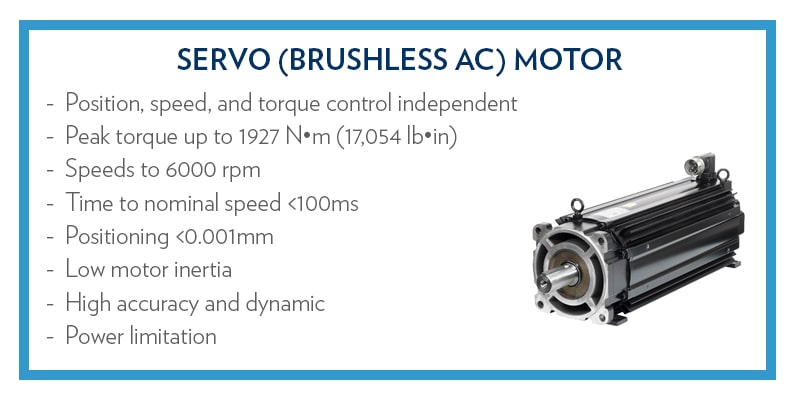

There is a fundamental difference in the construction and performance of the motors offered for VFD and servo applications. There are two types, asynchronous AC (or induction) motors and permanent magnet servo motors. The iron core magnets that are typically used in AC induction motors have less magnetic strength as compared to the neodymium magnets used in servo motors. This means a difference in power output per frame size of your motor based on the type of motor you choose. As an example, a 1 horsepower induction can be more than twice the physical size of a ‘comparable’ servo motor with respect to power output.

(Learn more by reading How Do I Choose an Electric Motor?)

There are some considerations when selecting asynchronous AC (induction) motors—largely around where the motor starts making usable torque.

Servo motors come in both medium and low inertia versions to best match performance with your application. These motors use high-strength neodymium magnets in their construction for higher torque density per frame size of the motor. In addition, they have integral feedback built in for tight, closed-loop control. These motors are also available in an IPM (internal permanent magnet) design for continuous duty applications.

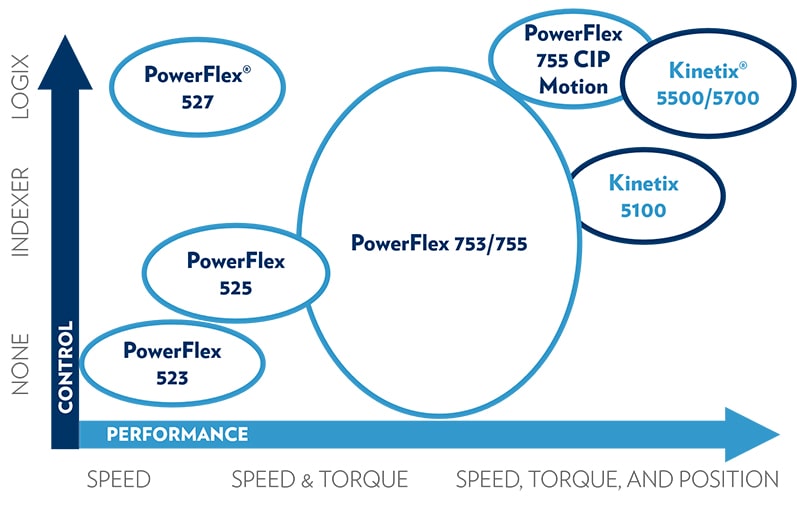

In addition to sizing your motor, when we look at drive/motor performance we need to consider where your drive/motor combination fits relative to your application requirements.

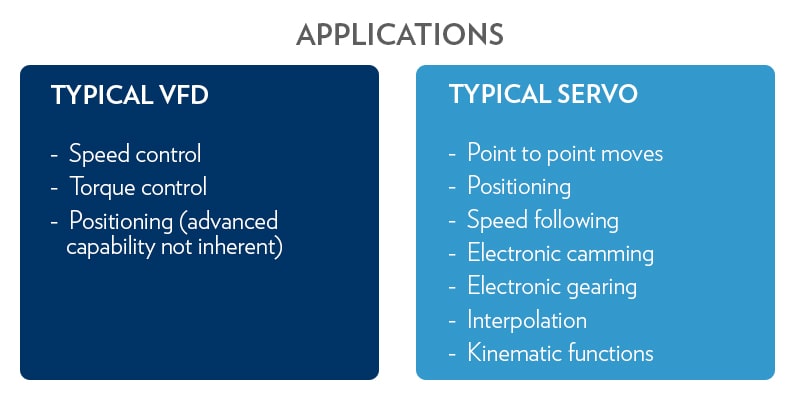

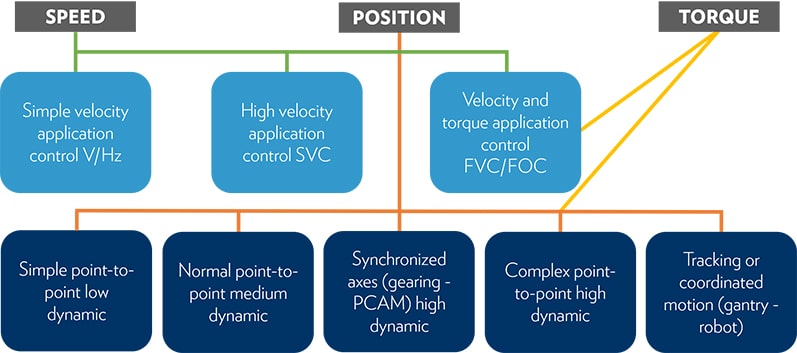

Then there are the specifics of the application. Do I just need velocity control? Do I need to follow a complex cam profile? Am I making repetitive moves with high accuracy? Do I need control over torque based on the process I am running? The chart below is a good general guideline for determining where to start.

The control type you require will help you to define your technology!

Regarding control response performance, variable frequency drives are typically slower than servo drives. As an example, the overall response to an error between a command and actual reference to a motor is slower in a VFD (1 millisecond) as compared to a servo drive (125 microseconds). It’s all about the bandwidth in the drive!!!

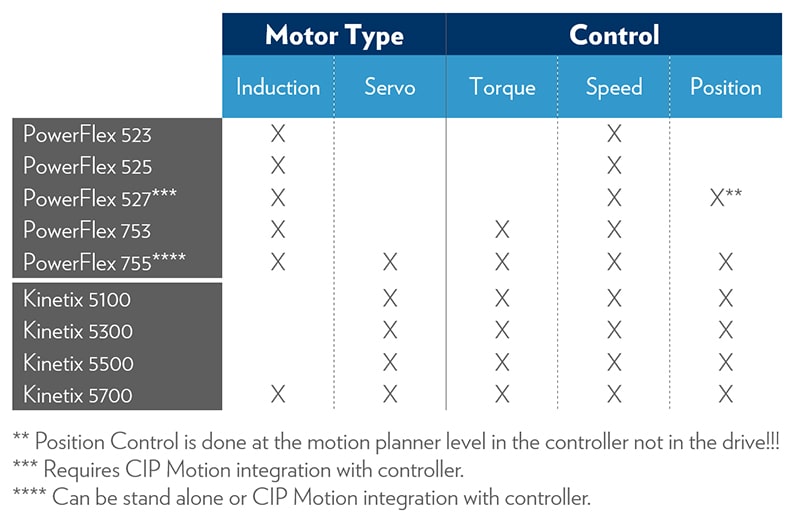

Let’s compare motor/drive control with the motor type supported as it relates to the type of control desired.

requires, and there are applications that are unquestionably VFD based on what the system performance requires. It is the gray area where we need to be diligent in asking questions to understand and determine what is best in the end for what we are trying to accomplish.

When it comes to, it simply comes down to this:

And if you’re still confused about what direction to take, VFD or servo contact us today and we’ll set you straight!!