Blog > Automation > VFD Series Part 3: Motor Cable Length Matters

VFD Series Part 3: Motor Cable Length Matters

8/19/16 | Kevin Beach, Rexel Technical Consultant

Blog > Automation > VFD Series Part 3: Motor Cable Length Matters

8/19/16 | Kevin Beach, Rexel Technical Consultant

We are often asked by customers “How long can my motor cables be when using a VFD?” Well, the simple answer is, there really isn’t a simple answer. This post looks at motor cable lengths and how to get the longest length possible. First and foremost!! If your system is not grounded and bonded correctly, then none of what follows applies. That being said, let’s talk about the motor cable itself as using the wrong cable can get us off to a really bad start.

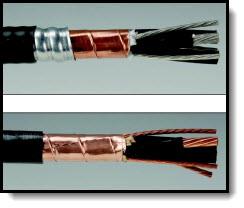

We have VFD rated cables today which provide not only the conductors and jacketing, but also shielding to contain the noise within the cable and keep the radiated noise from getting to the drive. When the shield is properly bonded at both ends, it keeps the inverter generated noise contained within the drive/motor circuit. Another option is the armored cables. These provide the full complement of conductors and employs continuous aluminum armor which provides most of the advantages of shielding and adds considerable mechanical strength and higher resistance to moisture. While the VFD rated cable doesn’t really make a difference in motor lead length it will make a big difference with noise issues. This is Lapp Group’s VFD Cable Selection Tool which will assist in VFD cable sizing.

Now, how far away from the motor can we mount the drive? Wiring and Grounding Guidelines for Pulse Width Modulated (PWM) AC Drives from Rockwell Automation® is a complete guide to everything about wiring and grounding, both of which need to be done correctly to maximize motor cable lengths.

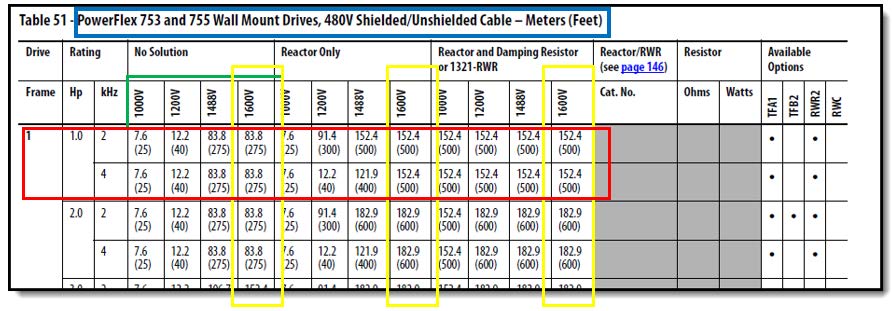

Let’s review this chart taken from the manual mentioned above and try to see what it’s telling us. First, be certain you’re using the correct drive and voltage as the distances change with voltage (blue box above). Then look for the proper frame size and HP (red box above). Keeping in mind, of course, that there can be 2 frame sizes for a given HP (or kW). Now we look at the green box. This reflects the motor you’re using, specifically the Corona Inception Voltage (CIV) of the motor itself. One of the phenomena associated with all energized electrical devices, including electric motors, is corona. The localized electric field near a conductor can be sufficiently concentrated to ionize air close to the conductors. This can result in a partial discharge of electrical energy called corona discharge, or corona. If you remember hearing the buzzing noise from high-voltage lines, this is the audible noise from the corona.

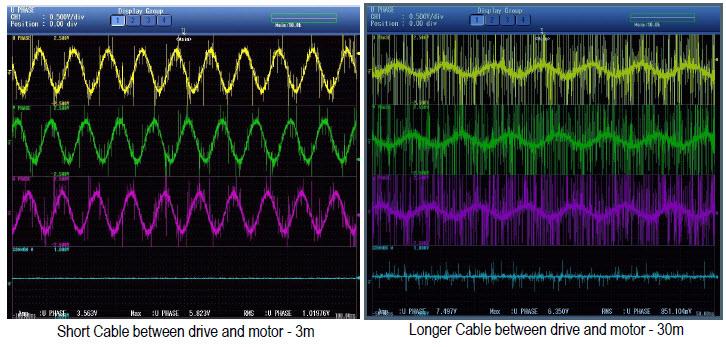

So how does the motor’s CIV impact us? There are typically three sources of impedance in any VFD system: the drive, the cable, and the motor. When the drive sends output sine waves down the cable to the motor, they reach the motor and, due to the motor’s impedance, reflect back towards the drive, while the drive is continually sending sine waves to the motor. These sinewaves are at 650 volts and when they combine or stack (out and back) they total 1300 volts. Now, if your motor is rated for 1000 volts, well, let’s just say this is a very bad thing for the motor, with a lot of black smoky stuff resulting.

For this reason, today’s Vector Duty motors are 1600 CIV, and, as a result, are far better suited for use with VFDs. So, let's look at those columns (yellow boxes where they intersect with red). With just a drive and vector duty motor, the longest lead length is 500 feet. And this is absolutely total cable length including up to the ceiling and down to the submersible pump; not just how far apart they are from each other in a straight line.

Not that there aren’t options to attain longer lengths because there certainly are, but these are all at additional cost. The takeaway here is it is always preferable to locate the drives as close as possible to the motor.

If this is not possible, the first option would be a terminator box. This mounts at the motor and gives runs up to 600 feet with no voltage drop. Using this device, we can get the drive and motor combination to about 600 feet total cable length.

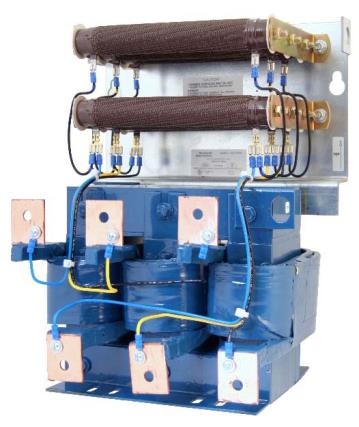

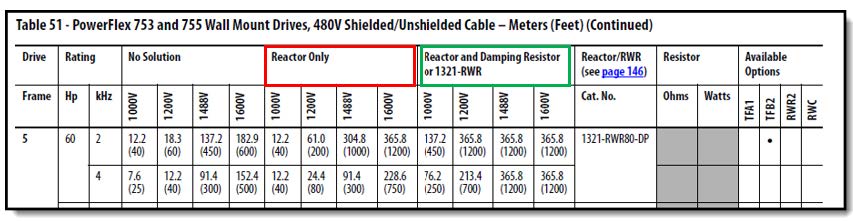

Looking at the columns in the chart for Frame 6 750 class drives (below, 1600V under the red boxes), the next option would be to add an output line reactor between the motor and VFD. This device mounts at the drive and slows the rise time and allows longer cable lengths but there is a voltage drop.

The third option is a Reflected Wave Filter or RWR drives (below, 1600 V under the green boxes). This device mounts at the drive as well and limits the peak voltage on the line. In doing so there can be cable lengths of 1200 feet but with voltage drop.

The line reactor and reflected wave filter options are in the 1600V columns below the red and green boxes in the above chart.

So, what’s this thing about voltage drop? I mentioned it three times in the last three paragraphs so it must be important., Well it is!! Most simply it is the charging current of the cable itself which can be fairly substantial in very long lengths. With a VFD rated cable, this could be as much as an amp for every 100 feet of cable length. This is of particular concern when using smaller VFDs as shown by the limited distance of 600 feet for the frame 1 PowerFlex 755, the smallest frame offered. The frame 6, 7 and 8 drives can go to 1200 feet as you can see in the chart above.

Now, what do I do if I’ve got a problem in the field and don’t have any of the options in place? There is an adjustable factor which may come in play. In PWM-based VFDs, there is something called carrier frequency which is the rate at which output transistors are gated or turned on, usually from 2 to 15 kHz. Higher values yield better current waveform, but more VFD losses. Try incrementally reducing the carrier frequency to as low as 2 kHz and see if that helps. If not, contact your Drive Specialist for help in selecting the correct solution. We can bring many different technical resources to aid in determining the best solutions for your needs.

As always, this is really intended to be a quick snapshot of the topic but there could be a thing or two in this you might not have known previously. For more complete information on all this, contact us! we are here to help. Really!!

This is part three of our popular, on-going variable frequency drives (VFD) series. Don’t miss the rest of the series: